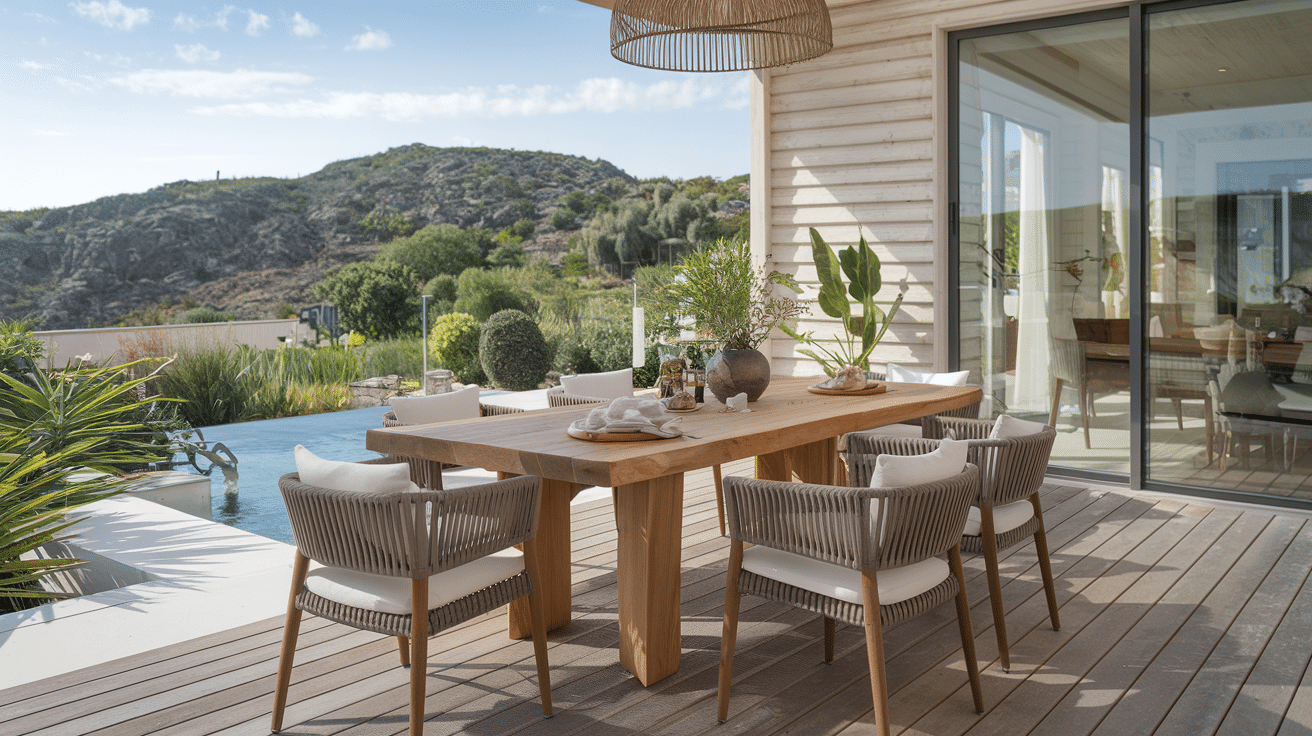

How to DIY Outdoor Dining Table for Your Backyard

Making your outdoor dining table can be a fun weekend project that saves money while adding a personal touch to your backyard space.

Many store-bought options come with steep price tags, but building one yourself costs much less and lets you choose the exact size, style, and finish that fits your outdoor area.

The satisfaction of creating something with your own hands adds extra meaning to family gatherings and meals shared around your table.

Plus, you can build it to last with quality materials that withstand your local weather conditions.

With some basic tools and simple instructions, you’ll have a beautiful new table ready for summer entertaining.

Choosing the Right Materials for Your DIY Outdoor Dining Table

Building an outdoor dining table requires careful material selection to ensure durability and longevity. This guide will help you choose the best materials for your project.

1. Best Woods for Outdoor Tables

- Cedar: Naturally rot-resistant, lightweight, and weathers to a beautiful silvery gray.

- Merbau: Dense hardwood with excellent weather and decay resistance.

- Treated Pine: Budget-friendly option that withstands outdoor conditions with proper maintenance.

2. Sustainable and Budget-Friendly Options

- Use reclaimed wood from salvage yards or local sources.

- Choose FSC-certified timber.

- Opt for low-VOC finishes and natural oil sealants.

3. Outdoor vs. Indoor Materials

Outdoor materials must withstand moisture, UV rays, temperature changes, and insect damage.

Never use indoor materials for exterior furniture, as they will quickly deteriorate.

Invest in wood and finishes designed for outdoor use to ensure your table remains functional and attractive for years.

Tools and Equipment You’ll Need

Building a dining table is an exciting woodworking project that requires careful preparation and the right equipment.

Your success depends on your skills and the appropriate tools to bring your vision to life.

Essential Tools for Building a Dining Table

Core tools form the foundation of your woodworking project, enabling precise cutting, drilling, measuring, and joining of wood components.

- Circular Saw or Table Saw: Primary cutting tool for lumber and sheet materials

- Power Drill: Essential for creating holes and driving screws

- Pocket Hole Jig: Creates strong, hidden joints for seamless assembly

- Tape Measure and Square: Ensures accurate measurements and precise angles

- Random Orbital Sander: Smooths surfaces for a professional finish

- Clamps: Holds pieces securely during cutting and assembly

- Wood Glue: Provides additional strength to wood joints

- Drill Bit Set: Allows for various hole sizes and types

- Screwdriver Set: Assists in manual and detailed fastening work

Optional Tools to Enhance the Process

Advanced woodworking tools that improve precision, efficiency, and potential for more complex design techniques.

- Track Saw: Provides ultra-precise, straight cuts

- Router: Enables decorative edge work and detailed joinery

- Planer: Helps level and smooth rough lumber

- Jointer: Creates perfectly straight board edges

- Kreg Jig: Advanced pocket hole system for complex joints

Safety Gear

Critical protective equipment to prevent injuries and ensure personal safety during woodworking projects.

- Safety Glasses: Protect eyes from wood chips and debris

- Hearing Protection: Guard against loud power tool noise

- Dust Mask: Prevent inhalation of wood particles

- Work Gloves: Protect hands from splinters and cuts

- Long-Sleeved Clothing: Minimize skin exposure to potential hazards

- Closed-Toe Shoes: Protect feet in the workshop

- First Aid Kit: Immediate treatment for potential minor injuries

Step-by-Step Guide to Building Your DIY Dining Table

Creating a dining table is a challenging but rewarding woodworking project that requires patience and precision.

Follow these key steps to bring your table to life.

1. Preparing the Wood

Select straight, high-quality lumber free from significant defects. Cut boards to the desired length using a saw, ensuring clean, square cuts.

Sand thoroughly, starting with coarse-grit sandpaper and progressing to finer grits for a smooth surface. Carefully remove all rough spots and splinters.

2. Assembling the Tabletop

Arrange boards to create an appealing grain pattern. Apply wood glue to the edges and use a pocket hole jig to create hidden joints.

Clamp boards tightly and secure with pocket hole screws. Sand the entire surface to create a smooth, flat tabletop.

3. Building and Attaching the Legs

Cut leg pieces to identical lengths, ensuring they’re perfectly square. Shape legs if desired using a table saw or hand plane.

Attach the legs to the tabletop using wood glue and strong fastening methods, such as pocket holes. Verify that the legs are perpendicular and level.

4. Attaching the Aprons and Stretcher

Cut apron pieces to fit precisely between legs. Attach aprons using pocket holes or mortise and tenon joints.

Install a centered stretcher near the bottom of the legs to provide additional stability.

Ensure all connections are tight and secure.

5. Ensuring Proper Alignment

Use a long level to check the tabletop for twists or warping. Verify that all legs touch the ground evenly, using shims if necessary.

Apply gentle pressure to test stability and make final adjustments. The goal is a solid, wobble-free table that will last for years.

Finishing Your DIY Dining Table

The right finish protects your handcrafted table from the elements and enhances its natural beauty.

Follow these key steps to achieve a professional, long-lasting result.

Sanding and Prepping for Finish

Sand the entire surface progressively from 120-grit to 220-grit sandpaper. Always sand with the wood grain to create a smooth surface.

Remove all dust with a tack cloth and wipe with mineral spirits to ensure a clean base for finishing.

Choosing the Right Finish for Outdoors

Select a finish that provides maximum protection against weather and UV rays.

Top options include:

- Marine varnish: Excellent water and UV resistance

- Spar urethane: Flexible coating that adapts to temperature changes

- Epoxy: Extremely durable, glossy finish

- Exterior polyurethane: Reliable all-around protection

Applying the Finish

Work in a clean, dust-free environment. Apply 3-4 thin, even coats using a high-quality brush or foam applicator.

Allow each coat to dry completely, lightly sanding between layers with 320-grit sandpaper. Ensure proper ventilation and follow the manufacturer’s instructions carefully.

Tips for Long-Lasting Durability

Protect your table from extreme conditions:

- Use a cover when not in use

- Clean regularly with mild soap

- Reapply finish annually

- Store indoors during harsh weather

- Address scratches or wear immediately

Proper care will keep your DIY dining table looking beautiful and functioning well for years.

Troubleshooting and Common Challenges

Woodworking comes with challenges, but understanding how to address them can help you create a professional-quality dining table.

Dealing with the Wood Movement

Wood naturally expands and contracts with temperature and humidity.

Prevent issues by:

- Using stable lumber

- Allowing wood to acclimate before working

- Using joints that accommodate wood movement

- Applying finish evenly to all surfaces

Ensuring Stability

Create a rock-solid table by:

- Cutting legs to the same length

- Using sturdy aprons and diagonal braces

- Checking surface levelness

- Using shims to correct minor irregularities

Fixing Mistakes During Assembly

Common problems have simple solutions:

- Misaligned joints: Use clamps, check squareness

- Uneven surfaces: Sand carefully

- Glue joint gaps: Disassemble and reapply carefully

- Tearout: Use backing boards when cutting

- Stripped holes: Reinforce with wood plugs

Maintenance and Care for Your Outdoor Dining Table

Regular maintenance keeps your outdoor dining table looking great and extends its lifespan.

Clean the table with a soft brush and mild soap, removing debris and wiping with the wood grain. Always dry thoroughly after cleaning to prevent water damage.

Inspect the table annually for wear, fading, or damage. Sand lightly and reapply marine varnish or exterior finish as needed.

Fill small cracks with wood filler, sand smooth, and touch up with a matching finish. Tighten any loose joints promptly.

Protect the table from prolonged exposure to harsh weather. Cover it when not in use and store it indoors during extreme conditions.

With consistent care, your handcrafted dining table will remain a beautiful outdoor centerpiece for years.

Conclusion

From wood selection to final finishing, you’ve learned the essential steps to creating a beautiful, functional piece of furniture.

The process allows for endless personalization—experiment with wood types, leg designs, and finishes that reflect your unique style and complement your outdoor space.

Your handcrafted table is more than furniture; it’s a personal achievement.

We invite you to share your completed projects and woodworking tips in the comments below!