Floating Hardwood Floor: Complete Guide

Many owners choose this flooring option because it’s easier to install than traditional wood floors. You don’t need nails or glue, which means less mess and faster projects.

The click-together system lets you finish a room in just one day, even if you’ve never done flooring before.

It works over concrete or existing floors, and if you move, your floating hardwood floor moves with you. Real wood beauty with zero installation hassle!

What is a Floating Hardwood Floor?

A floating hardwood floor isn’t nailed or glued down. The planks snap together using click-lock or tongue-and-groove edges and rest on foam underlayment.

Only floating engineered wood floor types work this way because they have multiple layers that stay stable. Solid wood expands too much.

The top layer is real hardwood veneer, while the base layers prevent warping. Small expansion gaps around room edges let the wood move naturally without buckling against walls.

This installation method is easier and faster than traditional flooring. You can even install a floating floor yourself over a weekend.

Types of Floating Engineered Wood Floors

Floating engineered wood floors are a popular choice for modern homes because they’re easy to install and look great. Let’s look at the different types available so you can pick the perfect option for your space.

| CONNECTION METHOD | BY STYLE AND DESIGN | BY WOOD SPECIES | BY FINISH |

|---|---|---|---|

| Click-lock (no glue needed) | 1-strip (single plank look) | Oak floating floors | Wire-brushed |

| Tongue-and-groove (glued) | 2-strip design | Maple engineered options | Hand-scraped |

| Hybrid systems | 3-strip (longstrip) style | Hickory, walnut, cherry varieties | Smooth/traditional |

| Wide plank options | Exotic wood options | Distressed looks |

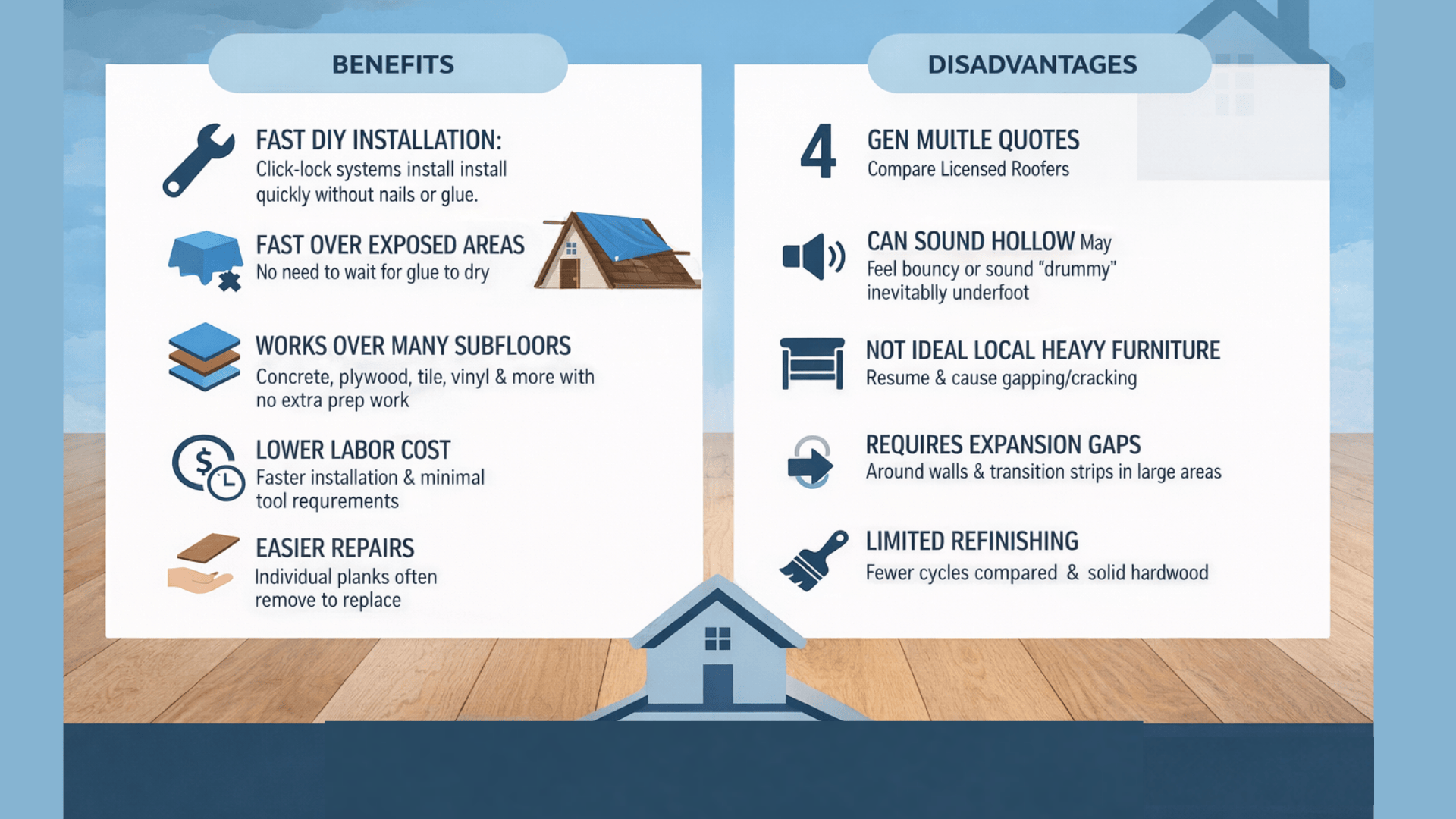

Floating Hardwood Floors: Pros and Cons

Thinking about floating hardwood floors for your home? Before you make a decision, it’s important to weigh the benefits and drawbacks to see if they’re right for you.

Benefits

- Fast DIY installation: Most floating engineered wood floor options use click-lock systems that install quickly without nails or glue.

- Works over many subfloors: Floating hardwood floor planks can be installed over concrete, plywood, tile, vinyl, and even some existing floors with the right underlayment.

- Lower labor cost: Because installation is faster and tool requirements are minimal, floating floors typically cost less to install than nail-down hardwood.

- Easier repairs: Individual planks can often be removed and replaced without tearing up the entire floor.

Disadvantages

- Can sound hollow: Floating floors may feel slightly bouncy or sound “drummy” without a quality underlayment.

- Not ideal for heavy furniture: Very heavy items like pianos, pool tables, or large kitchen islands can restrict movement and cause gapping or cracking.

- Requires expansion gaps: Floating engineered wood floors must have expansion space around walls and often need transition strips in large areas.

- Limited refinishing: Most engineered wear layers allow fewer refinishing cycles compared to solid hardwood flooring.

Floating vs. Other Installation Methods

Floating floors are popular because they install fast, cost less upfront, and work well over many subfloors, but they may feel less solid and sound louder than nail-down or glue-down options. Use the comparison below to choose the best method based on cost, durability, subfloor type, and long-term performance.

| FACTOR | FLOATING | NAIL- DOWN | GLUE-DOWN |

|---|---|---|---|

| Install + cost | Fast, lower cost | Slower, higher cost | Medium, higher materials |

| Feel + sound | Slightly hollow/bouncy | Most solid/quiet | Solid/quiet |

| Best for | DIY, concrete, condos | Wood subfloors, long-term | High-traffic, commercial |

| Repairs | Easiest | Harder | Hardest |

Top Floating Hardwood Floor Brands and Products

Choosing the right floating hardwood floor comes down to your budget, traffic level, and where you plan to install it. Below are the top floating engineered wood floor brands, organized by the best use case, plus where to buy and typical cost ranges.

1) Best Overall: Shaw

Shaw is a well-rounded brand of floating engineered wood floors with durable finishes, modern styles, and dependable click-lock systems.

- Best for: living rooms, family rooms, whole-home installs

- Where to buy: local flooring dealers, major flooring retailers

- Typical cost:$5 to $9/sq ft

- Link:Shaw Floors

2) Best Budget: TrafficMASTER

TrafficMASTER and similar Home Depot brands offer affordable floating hardwood floor options that are DIY-friendly and easy to find.

- Best for: rentals, bedrooms, guest rooms, budget remodels

- Where to buy: Home Depot

- Typical cost:$2 to $5/sq ft

- Link:TrafficMASTER at Home Depot

3) Best Mid-Range Value: Bruce

Bruce is a trusted mid-range brand that balances price, durability, and style for multi-room installs.

- Best for: dining rooms, living rooms, mid-traffic households

- Where to buy: Lowe’s, Floor & Decor

- Typical cost:$4 to $8/sq ft

- Link:Bruce Hardwood Floors

4) Best Premium Pick: Mullican (Engineered Lines)

Mullican is a premium engineered hardwood brand known for higher-end visuals and long-term durability in busy homes.

- Best for: high-traffic homes, long-term remodels, upscale finishes

- Where to buy: authorized flooring dealers

- Typical cost:$7 to $12+/sq ft

- Link:Mullican Flooring

Tools and Materials Required

Before installation, gather the right tools and materials to keep the job smooth and avoid delays. Most flooring installs use the same core tools, with a few extras depending on the method.

| TOOLS | UNDERLAYMENT | ADHESIVE (IF NEEDED) | SAFETY GEAR |

|---|---|---|---|

| Tape measure | Foam | Flooring adhesive | Gloves |

| Spacers | Cork | Trowel | Knee pads |

| Tapping block | Rubber | Adhesive remover | Safety glasses |

| Pull bar | Moisture barrier | Rags | Dust mask |

| Rubber mallet | Ear protection | ||

| Saw / cutter | |||

| Level |

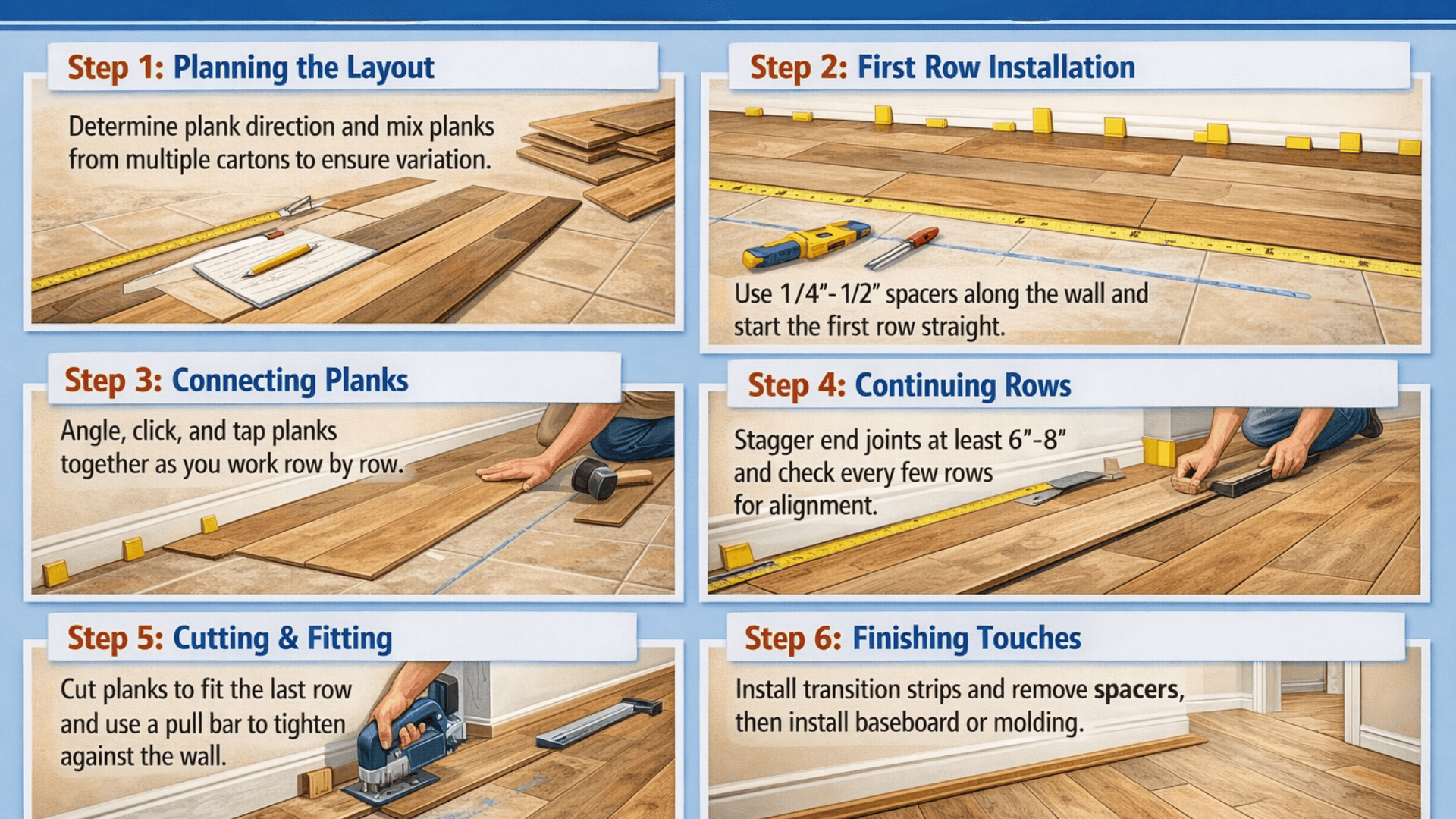

Step-by-Step Installation Process of a Floating Hardwood Floor

Installing a floating hardwood floor yourself can save you money and isn’t as hard as you might think. Follow these simple steps to get beautiful results without hiring a professional.

Step 1: Planning the Layout

Determine plank direction by running boards parallel to the longest wall or toward the main light source for visual appeal. Mix planks from multiple cartons to ensure color and grain variation throughout the room.

Calculate your starting point to avoid narrow cuts at the final row; ideally, the last row should be at least 2 inches wide.

Step 2: First Row Installation

Establish 1/4″ to 1/2″ expansion gaps along all walls using spacers to allow for seasonal movement. Select the straightest wall as your starting point, and position the planks with the tongue side facing the wall.

Ensure the first row is perfectly straight using a chalk line or laser level, as this determines alignment for the entire floor.

Step 3: Connecting Planks

For click-lock systems, angle planks at 20-30 degrees, insert the tongue into the groove, and press down until they click into place.

For tongue-and-groove with glue, apply a thin bead of flooring adhesive along the groove before connecting planks. Use a tapping block and rubber mallet to gently tap planks together, avoiding direct hammer strikes that can damage edges.

Step 4: Continuing Rows

Stagger end joints by at least 6-8 inches between adjacent rows to create a natural, structurally sound pattern. Maintain proper alignment by checking every few rows with a straight edge and adjusting as needed.

Measure and cut the planks carefully to fit around doorways, leaving some expansion gaps. Don’t forget to use transition strips to cover the space smoothly and neatly.

Step 5: Cutting & Fitting

Carefully measure and cut the last row to fit perfectly, making sure to leave the right expansion gap along the wall. This step helps ensure everything fits nicely and works well.

Use a jigsaw or handsaw to cut around obstacles like pipes, vents, and corners, leaving 1/4″ clearance around protrusions. A pull bar helps tighten the final row into place when a tapping block won’t fit.

Step 6: Finishing Touches

Install transition strips at doorways and where flooring meets other surfaces using the manufacturer’s recommended methods.

Remove all spacers once installation is complete, and install baseboards or quarter-round molding to cover expansion gaps. Trim door jambs if necessary so flooring slides underneath for a clean, professional appearance.

Best Uses and Ideal Locations for Floating Hardwood Floors

Floating hardwood floors excel in specific environments where traditional nail-down installation proves challenging or impractical. Understanding where these floors perform best—and where they fall short—helps you maximize your investment and avoid costly mistakes in unsuitable locations.

- Perfect for Basements and Below-Grade Spaces: Ideal for basements where moisture prevents nail-down installation. The floating method with vapor barriers and underlayment provides moisture protection. Maintain 35-55% humidity for optimal performance and longevity.

- Excellent for Condos and Upper Floors: Multi-story buildings benefit from reduced installation noise and sound-dampening underlayment. Meets building codes and HOA requirements while minimizing neighbor disruption during quick installation process.

- Great for Living Rooms, Bedrooms, and Dining Areas: Perfect for moderate-traffic residential spaces with easy DIY installation. Compatible with radiant heating systems. Avoid extremely heavy furniture to prevent plank separation or buckling.

- Use Caution in Kitchens and High-Moisture Areas: Requires a waterproof underlayment and immediate cleanup of spills near sinks or dishwashers. Not recommended for bathrooms, laundry rooms, or mudrooms due to moisture exposure and warranty exclusions.

- Not Recommended for Heavy Equipment or Commercial Spaces: Avoid under pool tables, pianos, or safes as weight causes buckling. Not suitable for commercial high-traffic areas or spaces with fixed cabinetry needing expansion room.

Maintenance and Care Tips for Floating Hardwood Floors

Proper maintenance extends the life and beauty of floating hardwood floors while preventing costly repairs. Following manufacturer-recommended care routines and addressing issues promptly keeps your floors looking pristine for decades.

- Daily and Weekly Cleaning Routine: Sweep or vacuum daily with soft-bristle attachments, then damp mop weekly using pH-neutral hardwood cleaners. Never wet mop, steam clean, or use oil soaps, wax, or ammonia-based products that damage finishes.

- Maintain Proper Humidity Levels (35-55%): Use humidifiers in winter and dehumidifiers in summer to prevent gapping or cupping. Install a hygrometer and run HVAC consistently, as extreme humidity fluctuations void warranties and cause permanent damage.

- Prevent Scratches and Everyday Damage: Place felt pads under furniture, use protective mats under rolling chairs, and trim pet nails regularly. Use area rugs in high-traffic zones and immediately clean spills to prevent water stains or finish damage.

- Fix Common Issues Promptly: Address gaps by increasing humidity so boards close naturally, eliminate squeaks with talcum powder between planks, and replace damaged planks by disassembling from the nearest wall using proper removal techniques.

- Long-Term Protection and Refinishing: Recoat floors every 3-5 years with manufacturer-approved finishes to refresh appearance. Use window treatments to minimize UV fading and document professional maintenance for warranty coverage and resale value.

Wrapping It Up

A floating hardwood floor offers the perfect balance of beauty, affordability, and ease of installation for any owner.

If you’re renovating your basement or living room, this diverse option delivers real-wood grace without the hassle of traditional installation.

Ready to alter your space? Choose your planks, gather your tools, and start your DIY project this weekend. With proper care, your new floors will look stunning for decades. Don’t wait; your dream floor is just one project away!