Complete Guide to Concrete Driveway Resurfacing

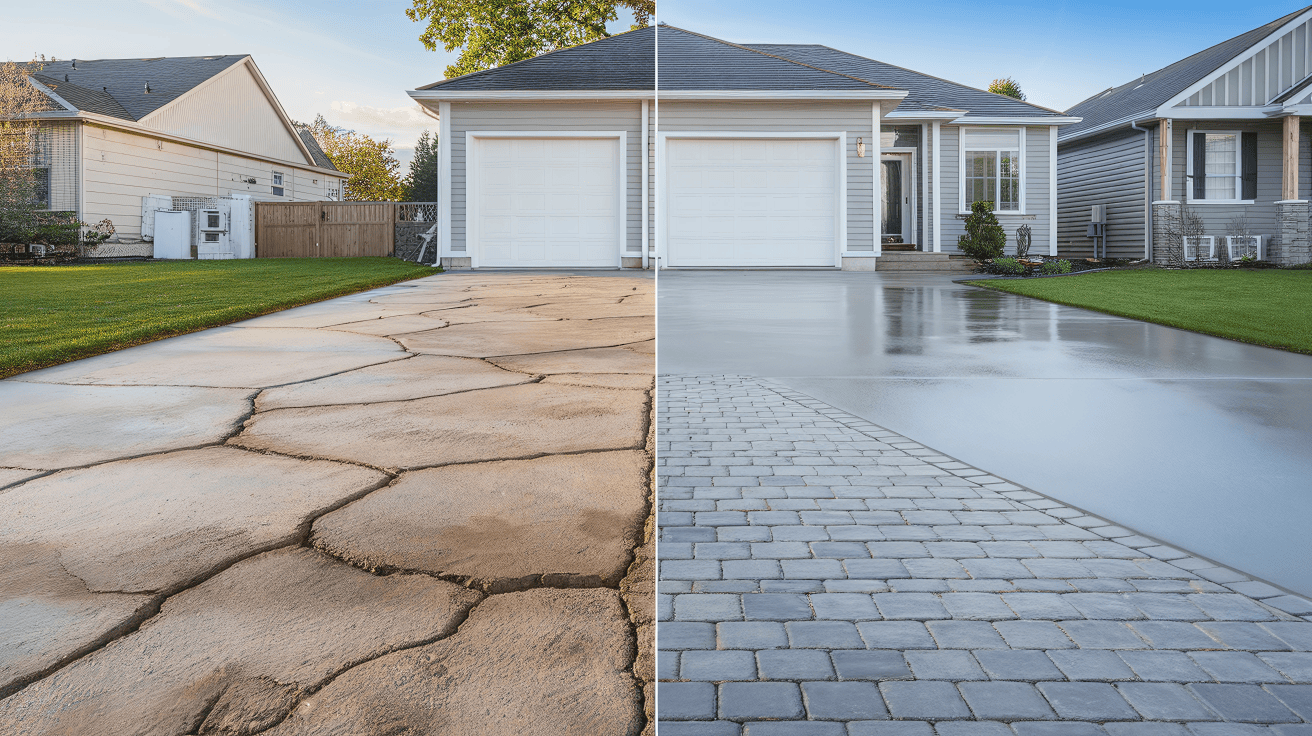

Is your concrete driveway showing signs of wear and tear? Cracks, stains, or weather damage can make your driveway look old and uninviting.

But don’t worry, concrete driveway resurfacing is a cost-effective solution to restore its appearance and extend its life.

In this guide, I’ll walk you through the benefits of resurfacing, the step-by-step process, and the tools you’ll need for a successful project.

If you’re considering a DIY approach or hiring a professional, you’ll find everything you need to make an informed decision. Let’s figure this thing out.

Benefits of Resurfacing Your Concrete Driveway

Concrete driveway resurfacing offers numerous benefits for homeowners seeking to enhance their property’s appearance and functionality.

This process provides a cost-effective solution that significantly enhances your home’s curb appeal while addressing common surface issues.

Key Benefits Include:

- Extends driveway lifespan by 10-15 years: When properly maintained, it makes for a smart investment that enhances property value.

- Addresses minor cracks, stains, and weathering damage: Fixes these issues without needing a full replacement, saving time and money.

- Allows creative customization: Offers options like stamped patterns, color integration, and textured finishes that match your home’s style for a fresh, modern look.

- Quick installation (1-3 days): Depending on the driveway size, with minimal disruption, vehicles can be used 24-48 hours after curing.

- Low maintenance: Requires less upkeep than other materials and provides better traction and safety, offering a balanced solution between repairs and replacement.

Concrete Driveway Resurfacing Step-by-Step Process

Learn how to resurface your concrete driveway with this simple, step-by-step guide for lasting and smooth results.

Tools and Materials Required

Gather these essential tools and materials before starting your project to ensure proper surface preparation, crack repair, material application, and professional-quality finishing results.

- Poly-Bond (cementitious bonding adhesive)

- Sand (for thicker applications and filling gaps)

- Water (for mixing)

- Pressure washer (for surface cleaning)

- Mixing equipment

- Sponge float (for smoothing)

- Trowel (for application)

- Broom or scratcher (for texture finish)

Step 1: Preparation

Clean the driveway: Start by pressure washing the driveway to remove any dirt, debris, and excess tar or asphalt. Ensure the surface is completely clean for optimal adhesion.

Assess the damage: Inspect the driveway for cracks or large gaps. These may need to be filled or patched before the coating can be applied.

Step 2: Fill Cracks and Gaps

Fill minor cracks: Use concrete crack filler to fill smaller cracks, smoothing them out with a putty knife.

Fill larger gaps: For larger damaged areas, use a quick-setting concrete mix to fill in and level out the surface. Allow this to cure for 24 hours before proceeding.

Step 3: Mix Poly-Bond

Prepare the Poly-Bond mixture: Poly-Bond is a cementitious bonding adhesive. Mix it with sand to thicken the material where necessary. This will allow the mixture to fill deeper gaps effectively.

Note: Poly-Bond is typically used in thinner applications (approximately 1/8″ to 1/4″), but for larger cracks, you can add sand to thicken the mixture.

Step 4: Apply the Base Coat

Spread Poly-Bond: Using a trowel or squeegee, spread the Poly-Bond mixture evenly over the driveway, working in small sections to maintain a wet edge.

Skim the surface: Ensure the material is spread evenly, filling in any cracks or rough areas.

Smooth the coat: Once applied, use a float to smooth and level the surface.

Step 5: Add Texture

Create a textured finish: While the surface is still workable, decide on your desired texture. For slip-resistance, use a broom to create a brushed texture. If you prefer a smooth finish, leave it as is.

Optional: You can also use stamp mats for stone or brick patterns if desired.

Step 6: Apply Color and Sealer

Add color (optional): If you want to color the driveway, apply colorants or stains while the surface is still slightly wet.

Apply concrete sealer: After the material has cured for 24-48 hours, apply a concrete sealer using a roller or sprayer. This helps protect the surface and enhances the appearance.

Step 7: Final Touches

Let it cure: Allow the driveway to cure fully for 24-48 hours before using it.

Review the result: After the curing time, inspect the driveway. The Poly-Bond coating should be strong, durable, and weather-resistant, lasting much longer than traditional methods.

For a more detailed walkthrough of the process, check out the concrete driveway resurfacing video tutorial below:

Types of Resurfacing Options

Choose from five resurfacing options, ranging from budget-friendly concrete resurfacer ($ 2-$4/sq ft) for basic wear to premium stamped concrete ($8-$ 12/sq ft) that mimics the look of stone or brick for maximum curb appeal.

1. Concrete Resurfacer (Cement-Based) – $2-4/sq ft. Budget-friendly thin coating, ideal for minor wear and small imperfections. Apply with a squeegee in 1/16″ thickness. Limited to basic gray color, but easy DIY application.

2. Acrylic Resurfacer (Polymer-Based) – $3-6/sq ft. Flexible polymer formula, resists cracking with multiple color options. Mix according to directions and apply with roller or squeegee. Better durability than basic resurfacer.

3. Epoxy Coating (Durable, Protective) – $4-8/sq ft. Heavy-duty two-part system requiring precise mixing and application. Prime the surface first, then apply epoxy with a roller. Creates a chemical-resistant, high-gloss finish ideal for high-traffic areas.

4. Concrete Overlay (Thicker Layer, New Design/Pattern) – $6-10/sq ft. Apply 1/4″ to 3/8″ thick using a trowel and float. Allows complete design freedom with textures and patterns. Mix small batches and work quickly before the mixture sets.

5. Stamped Concrete (Decorative, Mimicking Stone/Brick) – $8-12/sq ft. Pour the overlay material, then immediately press the stamp mats while they are still wet. Requires timing and technique. Apply release agent first, then color hardener for an authentic stone/brick appearance.

Disclaimer: The prices listed above are general estimates and can vary based on location, materials, labor, and project size. Always check with local suppliers or contractors for accurate pricing in your area.

Considerations for Choosing Resurfacing Methods

Choose your resurfacing method by balancing budget, traffic needs, aesthetics, and driveway condition, from basic options for light use to premium overlays for heavy traffic.

Here are some considerations you should keep in mind:

- Cost: Budget drives decisions – concrete resurfacer costs the least, and stamped concrete costs the most. Factor in materials, tools, and labor.

- Durability: Light-use driveways can handle basic resurfacing, while heavy traffic requires epoxy or overlays. Consider local climate conditions.

- Desired Look: A basic resurfacer yields industrial results, while stamped concrete mimics the appearance of stone/brick. Choose based on home style.

- Condition: Surface wear is suitable for resurfacing; major structural damage requires replacement. Honest assessment prevents costly mistakes.

DIY vs. Professional Help

Here’s a quick breakdown of when to tackle concrete driveway resurfacing yourself versus calling in the professionals:

| Project Type | DIY or Professional | Why |

|---|---|---|

| Basic concrete resurfacer | DIY | Easy mixing, standard tools, forgiving application |

| Acrylic overlays | DIY | Straightforward process, good for handy homeowners |

| Light wear/minor issues | DIY | Cost-effective, simple, clean-mix-apply process |

| Stamped concrete | Professional | Requires specialized tools and expertise |

| Epoxy coatings | Professional | Complex application, weather-sensitive |

| Extensive repairs | Professional | Need to diagnose underlying problems |

| Major cracks | Professional | Structural issues require expert assessment |

| Drainage problems | Professional | Complex troubleshooting needed |

| Intricate patterns | Professional | Specialized skills for quality results |

Common Problems and How to Fix Them

Even the best concrete driveway resurfacing projects can run into issues, but most problems have straightforward solutions. Here’s how to tackle the most common challenges you might face:

- Cracks: Small hairline cracks can be easily fixed with crack filler or caulk before resurfacing. Wider cracks or ones that return quickly indicate foundation problems that resurfacing can’t solve.

- Uneven Surfaces: Minor dips and bumps can be leveled with self-leveling concrete or thicker overlays, while grinding works for small high spots. Significant unevenness indicates concrete failure that requires replacement rather than resurfacing.

- Lifespan Issues: Basic resurfacing lasts 3-5 years, acrylic overlays last 5-8 years, and epoxy/concrete overlays last10-15+ years. Premature failure often stems from poor preparation, adverse weather conditions, or incompatible materials.

- Prevention Tips: Seal your resurfaced driveway annually, clean up spills promptly, and avoid using de-icing salts whenever possible. Regular maintenance doubles the lifespan of most resurfacing materials.

Most resurfacing problems have simple fixes, but proper preparation, material selection, and annual maintenance are crucial to maximizing the lifespan of your investment, which ranges from 3 to 15 years.

Conclusion

I’ve found that concrete driveway resurfacing is most effective when addressing surface-level issues, such as minor cracks and stains.

It’s my go-to recommendation for fixing your driveway without replacement costs.

Choose basic resurfacing for simple refreshes, acrylic overlays when you want durability and color, or stamped concrete for dramatic curb appeal.

Major structural damage requires full replacement. I’ve learned resurfacing won’t solve your underlying problems.

If you found this useful, be sure to read other guides available on the website for additional home improvement projects.