15 Types of Wood Joinery and What They’re Good For

Every project starts with a few pieces of wood and an idea. But it’s the way those pieces come together that makes your work hold up over time.

That’s where wood joinery comes in. It’s not just about sticking boards together; it’s about doing it right.

I’ve been through the trial-and-error stage, and I know how confusing it can feel at first.

So in this guide, I’ll walk you through all the main types of wood joinery, explain how each one works, and help you pick the best fit for your projects.

You’ll also find tips on choosing joints by purpose, tool basics, and a simple chart to compare them all in one place.

Types of Wood Joinery

Now that you know how to choose the right joint, let’s look at the most common types. Each one works a little differently, and some are better for certain projects than others.

I’ll break them down so you can see what fits your build.

1. Butt Joint

A butt joint is where one board is placed directly against another and joined using screws or nails. This type of joint doesn’t require special cuts or fancy tools, making it the easiest for beginners.

It’s mostly used where appearance doesn’t matter much, and strength isn’t a priority.

- Best use cases: Wall frames, quick utility shelves, temporary boxes

- Strength rating: Low

- Tools needed: Saw, drill, screws, clamps (optional)

- Mistakes to avoid: Don’t rely on nails or screws alone; use glue if possible, and always check for square alignment.

2. Mitered Butt Joint

This joint connects two boards cut at an angle, usually 45 degrees. It hides the end grain, so it looks cleaner than a standard butt joint.

However, it’s not much stronger unless reinforced with dowels or splines.

- Best use cases: Picture frames, door trims, decorative corners

- Strength rating: Low to medium

- Tools needed: Miter saw, glue, and clamps

- Mistakes to avoid: Make sure both angles are cut precisely. Mismatched cuts lead to gaps that weaken the bond.

3. Half-Lap Joint

In this joint, half the thickness of each board is removed so they sit flush when joined. It gives more surface area for glue and keeps parts from shifting out of place. It balances strength with simplicity.

- Best use cases: Framing structures, furniture supports, grid-style designs

- Strength rating: Medium

- Tools needed: Hand saw, chisel, or table saw with dado blade

- Mistakes to avoid: Removing too much material weakens the structure. Test-fit each joint before gluing.

4. Tongue and Groove

This joint uses a raised “tongue” on one edge that fits into a matching “groove” on the other. It’s often used to connect long boards side-by-side and keeps the surface flat.

- Best use cases: Hardwood floors, wall paneling, tabletops

- Strength rating: Medium to high

- Tools needed: Router with tongue and groove bits, clamps

- Mistakes to avoid: Avoid too tight or too loose fits. Both reduce strength and can cause gaps or cracks.

5. Mortise and Tenon

One of the oldest and strongest joints, it fits a square peg (tenon) into a square hole (mortise). When done right, it locks together tightly and supports a lot of weight.

- Best use cases: Chair legs, table frames, wooden bed rails

- Strength rating: High

- Tools needed: Chisel, saw, drill, mallet, glue

- Mistakes to avoid: Tenons that are too thin will wobble. Too tight and they may split the mortise.

6. Biscuit Joint

A biscuit joint joins boards along the edge by cutting matching slots and inserting oval biscuits. The glue causes the biscuits to swell slightly, locking the pieces together.

- Best use cases: Gluing panels, building large flat surfaces like desks or cabinet doors

- Strength rating: Medium

- Tools needed: Biscuit joiner, glue, and clamps

- Mistakes to avoid: Mismatched slot placement causes misaligned boards. Always mark edges before cutting.

7. Pocket Joint

This joint uses angled holes to connect boards with screws. It’s fast and easy, especially with a jig. The screws pull the boards tight and can be done without glue.

- Best use cases: Cabinet face frames, simple furniture, and baseboards

- Strength rating: Medium

- Tools needed: Pocket hole jig, drill, screws

- Mistakes to avoid: Using the wrong screw length can split the wood or give a loose joint.

8. Dado

A dado is a groove cut across the face of a board to accept another board’s edge. This keeps parts locked in place and increases surface area for glue.

- Best use cases: Bookshelves, drawer bottoms, cabinet sides

- Strength rating: High

- Tools needed: Table saw with a dado blade or router

- Mistakes to avoid: Too shallow, and it won’t hold. Too deep, and the board may become unstable.

9. Rabbet

A rabbet is a stepped edge cut into a board so that another board fits into it. Often used where backs need to sit flush or overlap slightly.

- Best use cases: Backs of cabinets, boxes, and window frames

- Strength rating: Medium

- Tools needed: Router, table saw, or rabbet plane

- Mistakes to avoid: Inconsistent depth or tearing out the corner edge during cutting.

10. Dovetail Joint

This joint has interlocking fingers that are visible from both sides. It combines strong hold with good appearance. A hand-cut dovetail shows skill and lasts a long time.

- Best use cases: Jewelry boxes, high-end drawers, and custom boxes

- Strength rating: Very high

- Tools needed: Dovetail saw, chisel, marking gauge, dovetail jig (optional)

- Mistakes to avoid: Cutting tails and pins too tightly or misaligning them can ruin the fit.

11. Half-Blind Dovetail

Like a through dovetail, but only visible from one side. It’s often used for drawer fronts where a smooth outside face matters.

- Best use cases: Drawer boxes, cabinets

- Strength rating: Very high

- Tools needed: Dovetail jig, chisel, saw

- Mistakes to avoid: Poor fit or spacing makes the joint weak and affects how clean it looks.

12. Sliding Dovetail

This version has a long groove in one board and a matching dovetail tongue on the other. It slides in like a lock and adds strength and alignment.

- Best use cases: Attaching shelves, drawer dividers

- Strength rating: High

- Tools needed: Router with dovetail bit

- Mistakes to avoid: Too tight and it won’t slide. Too loose and it won’t hold.

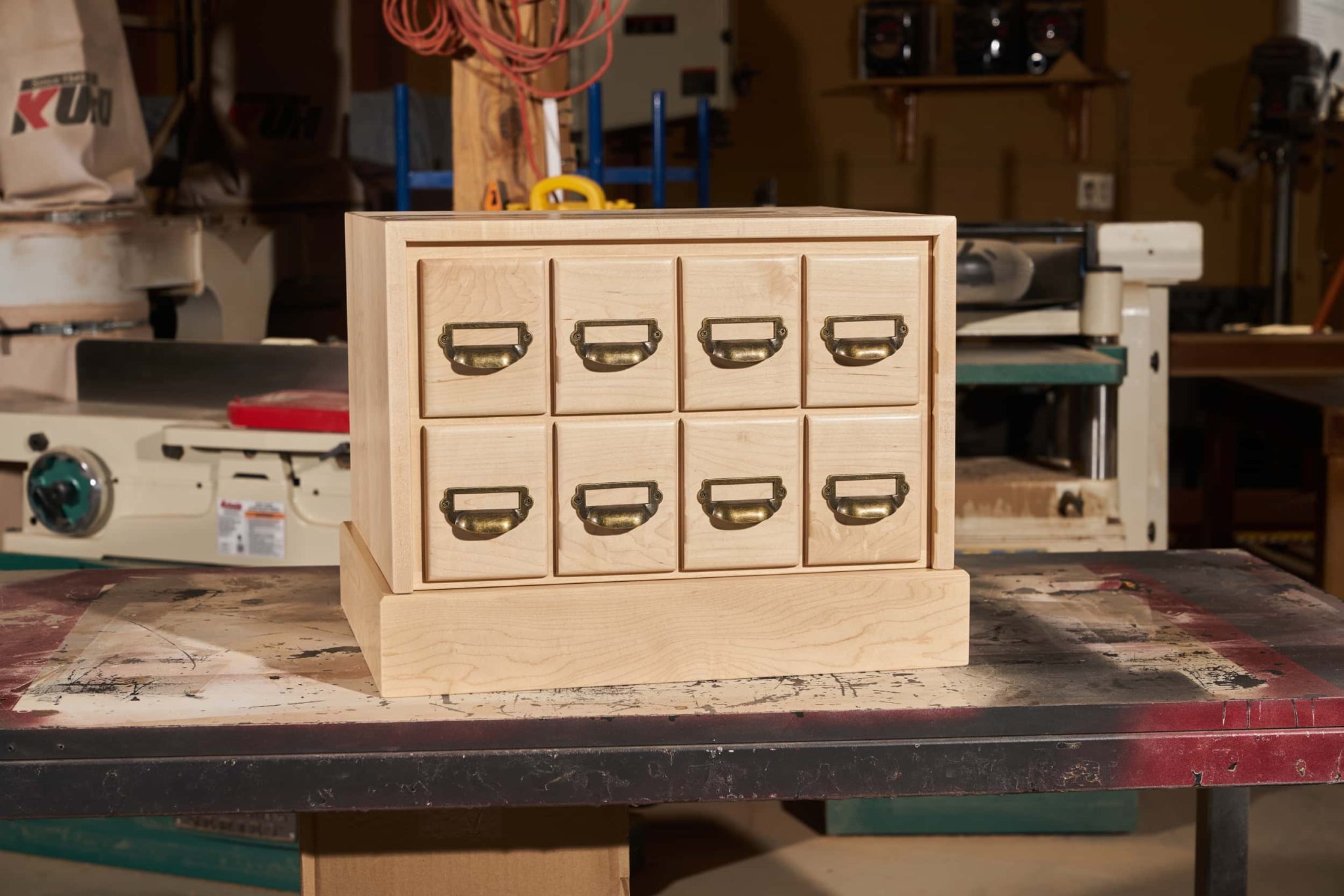

13. Box Joint

This joint uses square fingers that fit together across two boards. It’s easy to make with a jig and is almost as strong as a dovetail.

- Best use cases: Toolboxes, utility drawers, storage boxes

- Strength rating: High

- Tools needed: Dado blade, box joint jig, glue

- Mistakes to avoid: Inconsistent spacing or poorly cut fingers create weak spots or gaps.

14. Bridle Joint

This joint has a slot cut into one board and a matching tongue on the other. It looks like an open mortise and tenon. It’s easy to check for alignment and offers decent strength.

- Best use cases: Frames, bench legs, rail-to-post connections

- Strength rating: Medium to high

- Tools needed: Saw, chisel, clamp, glue

- Mistakes to avoid: Loose cuts weaken the grip. Measure and test-fit before gluing.

15. Scarf Joint

Used to join two boards end-to-end. Often cut at an angle or stepped to increase surface contact. It’s handy when you need longer pieces from shorter stock.

- Best use cases: Trim, beams, and long panels

- Strength rating: Low to medium

- Tools needed: Hand saw or circular saw, glue, and clamps

- Mistakes to avoid: Too shallow or short a cut can pull apart easily. Reinforce with glue and sometimes screws.

Wood Joinery Comparison Table

By now, you’ve seen how each joint works and where it fits best. But if you want a quick way to compare them all at once, the table below can help.

| Joint Type | Strength | Complexity | Best For |

|---|---|---|---|

| Butt Joint | Low | Very Easy | Framing, quick builds |

| Mitered Butt | Low | Easy | Trim, frames |

| Half-Lap | Medium | Moderate | Frames, furniture |

| Tongue & Groove | Medium | Moderate | Panels, flooring |

| Mortise & Tenon | High | Hard | Chairs, beds |

| Biscuit | Medium | Easy | Tabletops, panels |

| Medium | Easy | Cabinets, face frames | |

| Dado | High | Moderate | Shelves, cabinetry |

| Rabbet | Medium | Easy | Cabinet backs |

| Through Dovetail | Very High | Hard | Boxes, drawer sides |

| Half-Blind Dovetail | Very High | Hard | Drawer fronts |

| Sliding Dovetail | High | Hard | Shelving, drawer guides |

| Box Joint | High | Moderate | Boxes, utility drawers |

It’s helpful when you’re deciding which one to try next or when you’re working on a new project. Keep it handy so you can match each joint to the task without second-guessing.

Common Mistakes in Joinery and How to Fix Them

Even experienced woodworkers slip up sometimes. Joinery can look simple, but small details make a big difference.

Here are some common mistakes you might run into and how to fix them without starting over.

- Loose joints: This often happens when your cuts aren’t accurate. Always dry-fit the pieces first and adjust before gluing. A loose fit won’t hold under pressure.

- Gaps in the fit: These are usually caused by uneven cuts or poor clamping. Use clamps to pull the pieces tight and trim or recut as needed.

- Weak glue bonds: Dirty or dusty wood won’t hold glue well. Always wipe down your surfaces, spread glue evenly, and give it time to dry properly.

- Cracks or splits: This can happen if screws are driven without a pilot hole. Use the right size drill bit first, and never force hardware into dry or brittle wood.

- Misaligned cuts: Rushing through cuts can throw everything off. Double-check your layout lines, and use guides to keep cuts steady and square.

- Overtightened fasteners: Screws that go too deep can crush the wood fibers and ruin the grip. Stop once the joint feels snug, not crushed.

Conclusion

I’ve covered a lot, from basic joints to the more detailed ones, and now you’ve got a clear idea of how they work.

You saw what tools are helpful, what mistakes to avoid, and how to compare joints based on use. Everything was laid out to help you choose the right method without overcomplicating it.

If something felt new or confusing at first, that’s normal. The more you build, the easier these choices will get. Stick with it, and you’ll feel more confident every time.

Want to try more woodworking ideas or tips? Check out the other blogs on related tools, easy builds, or joinery tricks. There’s always something useful to learn next.