How Door Material Choices Affect Long-Term Maintenance

When shopping for a new entry door, the price tag you see is only part of the story. The real cost of door ownership reveals itself over the next 10 to 20 years through maintenance, repairs, and eventual replacement. A beautiful wood door that needs refinishing every three years can end up costing significantly more than a fiberglass alternative that requires little more than occasional cleaning. Understanding how different door materials perform over time helps homeowners make informed decisions that balance upfront investment with long-term value. In this guide, we’ll compare the three most popular door materials—wood, fiberglass, and steel—examining their maintenance demands, lifecycle costs, and ideal applications to help you choose the right option for your home.

Understanding the True Cost of Door Ownership

The sticker price of a door represents just the beginning of your financial commitment. Over the years, maintenance expenses, repair costs, and the timeline to replacement all factor into the total cost of ownership. A door that costs $800 initially but requires $200 in annual maintenance will ultimately exceed the total cost of a $1,500 door that needs virtually no upkeep.

Several factors drive these long-term costs. Climate exposure plays a major role—doors facing harsh sun, driving rain, or extreme temperature swings deteriorate faster than those in protected locations. Usage frequency matters too; a main entry door that opens dozens of times daily experiences more wear than a rarely used side entrance. Finish degradation varies dramatically by material, with some requiring frequent repainting or refinishing while others maintain their appearance for decades.

Lifecycle costs differ fundamentally from initial investment because they account for the hidden expenses of ownership. These include not just materials for refinishing but also labor costs if you hire professionals, the value of your own time for DIY maintenance, energy costs related to door efficiency, and the opportunity cost of dealing with repairs versus spending that time elsewhere.

When manufacturers or retailers describe a door as “low maintenance,” it’s worth understanding what that actually means. Truly low-maintenance options might need nothing more than occasional cleaning and perhaps a fresh coat of paint every decade. In contrast, materials marketed as requiring “minimal” maintenance might still demand regular sealing, refinishing, or adjustments that add up significantly over time.

Wood Doors: Classic Appeal with Ongoing Commitment

Wood doors offer unmatched natural beauty and traditional elegance, but they demand the most consistent attention of any door material. Understanding the maintenance requirements and long-term costs helps set realistic expectations for this classic choice.

Maintenance Requirements

Wood’s organic nature makes it susceptible to environmental factors that require ongoing management. Most wood doors need refinishing every two to five years depending on exposure levels. A door under a generous overhang in a mild climate might stretch to five years between treatments, while one facing afternoon sun or harsh weather may need attention every two years. This refinishing involves stripping old finish, sanding, applying new stain or paint, and adding protective topcoats—a labor-intensive process whether you tackle it yourself or hire professionals.

Moisture management represents another critical maintenance concern. Wood expands when it absorbs moisture and contracts as it dries, leading to warping, sticking, or gaps that compromise energy efficiency and security. Proper maintenance includes ensuring adequate sealing on all surfaces, monitoring for signs of moisture damage, and addressing issues before they become serious. In humid climates or locations with significant rainfall, this vigilance becomes even more important.

Hardware maintenance for wood doors requires regular attention as well. Hinges may need periodic adjustment as the door swells or shrinks with seasonal changes. Lock mechanisms should be lubricated annually, and you’ll need to check weatherstripping for gaps that develop as the wood shifts.

Long-Term Costs

The ongoing expenses of wood door ownership add up substantially over decades. Refinishing materials—stripper, sandpaper, stain or paint, and topcoat—typically cost $75-150 for a DIY project. Professional refinishing often runs $300-600 per treatment. Over 20 years with refinishing every three years, that’s six to seven cycles adding $450-900 in materials or $1,800-4,200 in professional costs.

Beyond routine refinishing, wood doors risk more serious damage. Rot can develop in areas where moisture penetrates, requiring wood replacement or repair that may cost several hundred dollars. Water damage to the bottom rail is particularly common and can necessitate partial or complete door replacement if caught too late. These potential repairs add uncertainty to the total cost equation.

With proper care, quality wood doors can last 20-30 years or more. However, neglecting maintenance can shorten this lifespan considerably, potentially requiring replacement in 10-15 years instead.

Best Use Cases

Wood doors make most sense in specific situations. They’re ideal for protected entryways with substantial overhangs that shield them from direct weather exposure. They suit homeowners who genuinely appreciate the aesthetics and craftsmanship of natural wood and don’t view regular maintenance as a burden. Historic homes or those with traditional architecture often demand wood doors to maintain authentic period character. If you have the time, inclination, and budget for ongoing care, wood doors reward you with timeless beauty and the satisfaction of maintaining a natural material.

Fiberglass Doors: The Modern Middle Ground

Fiberglass doors have evolved to offer the aesthetic appeal of wood without the demanding maintenance schedule, making them increasingly popular among homeowners seeking durability and appearance in one package.

Maintenance Requirements

The beauty of fiberglass lies in its minimal upkeep demands. Unlike wood, fiberglass doesn’t absorb moisture, so it won’t warp, crack, or rot regardless of humidity or rainfall. This stability means you won’t spend weekends monitoring for moisture damage or adjusting hardware as the door swells and contracts.

Refinishing needs are optional rather than mandatory. Many homeowners go 8-10 years or longer before repainting a fiberglass door, and some never repaint at all if they’re satisfied with the original finish. When you do decide to refresh the appearance, the process is straightforward—light sanding and a new coat of exterior paint—without the intensive stripping and preparation wood requires.

Routine maintenance consists mainly of occasional cleaning with mild soap and water, and periodic checks of weatherstripping and seals. These tasks take minutes rather than hours and require no special skills or materials.

The material’s resistance to warping, cracking, and weather damage means fewer emergency repairs and adjustments. The door maintains its fit in the frame year-round, preserving energy efficiency and security without intervention.

Long-Term Costs

Fiberglass doors represent a higher initial investment than basic steel doors and sometimes approach or match wood door prices, but ongoing expenses remain remarkably low. Over a 20-year period, you might repaint once or twice at a cost of $50-100 in materials for DIY work, or $200-400 for professional painting. Compare this to the thousands spent maintaining wood, and the value proposition becomes clear.

The material’s durability against dents and impacts means fewer repairs from accidental damage. While no door is completely impact-proof, fiberglass handles the bumps and knocks of daily life better than wood and resists denting better than lower-grade steel options.

Expected lifespan extends beyond 30 years with minimal intervention, and many fiberglass doors look nearly new after decades because the material doesn’t deteriorate the way organic materials do. Companies like Doornmore and US Door & More Inc demonstrate how quality fiberglass construction reduces long-term upkeep while maintaining appearance through advanced manufacturing techniques that create realistic wood textures and grain patterns without wood’s vulnerabilities.

Energy efficiency benefits persist throughout the door’s life as well, since fiberglass provides excellent insulation that doesn’t degrade. This translates to lower heating and cooling costs year after year.

Best Use Cases

Fiberglass excels in high-exposure locations where wood would suffer—entries facing full sun, locations with driving rain, or climates with extreme temperature swings. They’re perfect for homeowners who want the appearance of a wood door but lack the time or interest in regular maintenance. Busy families, vacation homes that sit unattended for months, and rental properties all benefit from fiberglass’s set-it-and-forget-it reliability. If you appreciate traditional aesthetics but prioritize practical durability, fiberglass offers the best of both worlds.

Steel Doors: Maximum Durability, Minimum Fuss

Steel doors prioritize security, durability, and affordability, making them a practical choice for many homeowners, particularly those focused on safety and minimal maintenance.

Maintenance Requirements

Steel’s maintenance demands center primarily on protecting the finish. Paint touch-ups for scratches and chips prevent rust from developing at damaged spots. While quality steel doors come with durable factory finishes, daily use inevitably causes some wear. Addressing these issues promptly with matching touch-up paint—a five-minute task—prevents minor damage from becoming major problems.

Rust prevention becomes more critical in coastal areas or high-humidity environments where salt air and moisture accelerate corrosion. Annual inspection of the door’s surface, particularly around hardware and the bottom edge, helps catch early rust formation. In these challenging climates, applying a fresh coat of rust-inhibiting primer and paint every few years provides extra protection.

Dent resistance varies based on the steel gauge and core material. Heavier-gauge steel resists denting better, while foam-core insulation provides more impact resistance than hollow cores. Even dent-resistant models may show damage from significant impacts, though this typically affects appearance rather than function.

Long-Term Costs

Steel doors offer the lowest maintenance requirements overall among the three materials. The main recurring expense involves repainting every 5-8 years to maintain appearance and protection, costing $40-80 in materials for a DIY project or $150-350 for professional work. Over 20 years, that’s two to four paint jobs totaling $80-320 in materials or $300-1,400 professionally.

These costs pale in comparison to wood door maintenance and even undercut the minimal expenses of fiberglass. The simplicity of steel maintenance—primarily just repainting when needed—makes budgeting straightforward with few surprise expenses.

Expected lifespan extends 30 years or more for quality steel doors, particularly when protected from rust through proper maintenance. The door’s structural integrity remains sound virtually indefinitely, with most failures involving finish deterioration rather than door failure.

Energy efficiency benefits provide another long-term cost advantage. Modern steel doors with polyurethane foam cores offer excellent insulation that reduces heating and cooling expenses year after year. This efficiency doesn’t degrade over time, providing consistent savings throughout the door’s life.

Best Use Cases

Steel doors shine in specific applications. They’re ideal for high-traffic areas where constant use would quickly damage less durable materials. Rental properties benefit from steel’s combination of low cost, minimal maintenance, and high durability. Security-focused installations take advantage of steel’s superior strength and resistance to forced entry. Budget-conscious homeowners who prioritize function over aesthetics find steel doors deliver excellent value, especially when appearance is less critical—such as doors from the garage into the home or side/back entries. For maximum durability with minimum fuss, steel is hard to beat.

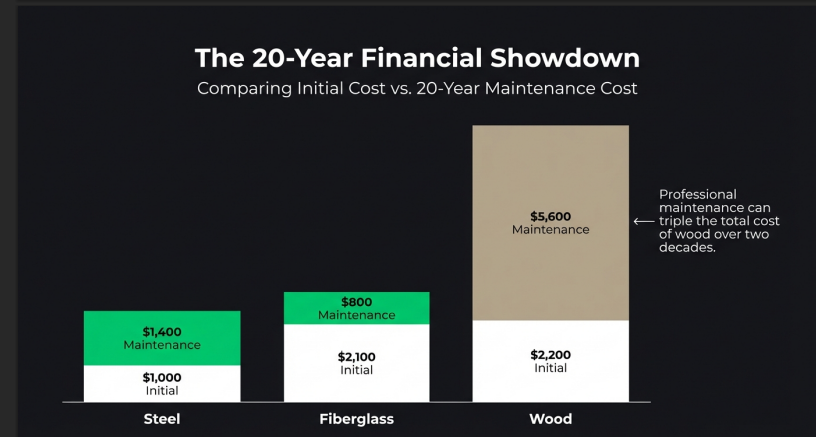

Side-by-Side Comparison: 20-Year Cost Analysis

Understanding the total cost of ownership requires looking beyond initial purchase price to account for maintenance, repairs, and energy impacts over time. Here’s how the three materials compare:

Initial Cost Ranges:

- Wood: $1,000-$3,500 (depending on species and craftsmanship)

- Fiberglass: $1,200-$3,000 (varying by style and quality)

- Steel: $500-$1,500 (based on gauge and core type)

Estimated Maintenance Frequency and Costs (20 years):

- Wood: Refinishing every 3 years (6-7 times) = $450-$900 DIY or $1,800-$4,200 professional; potential rot repairs $200-$800

- Fiberglass: Optional repainting 1-2 times = $50-$200 DIY or $200-$800 professional

- Steel: Repainting every 6 years (3-4 times) = $120-$320 DIY or $450-$1,400 professional

Total 20-Year Ownership Cost:

- Wood: $1,450-$4,400 (DIY maintenance) or $2,800-$8,500 (professional)

- Fiberglass: $1,250-$3,200 (DIY) or $1,400-$3,800 (professional)

- Steel: $620-$1,820 (DIY) or $950-$2,900 (professional)

Time Investment for Upkeep:

- Wood: 60-100 hours over 20 years (refinishing, monitoring, adjustments)

- Fiberglass: 5-15 hours over 20 years (cleaning, occasional painting)

- Steel: 10-20 hours over 20 years (touch-ups, periodic painting)

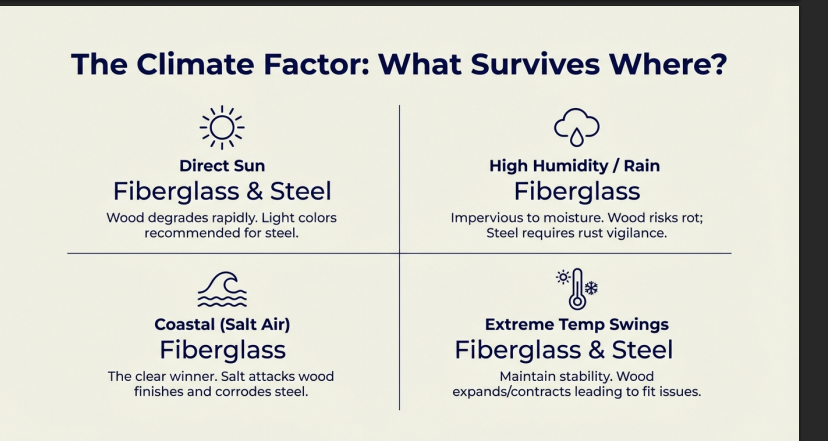

Climate Considerations:

Hot, sunny climates accelerate finish degradation on all materials but particularly stress wood, requiring more frequent refinishing. Fiberglass and steel handle intense sun well, though lighter colors help reflect heat.

Humid or rainy environments pose the greatest challenge for wood, making moisture management critical. Fiberglass excels here, remaining completely unaffected by moisture. Steel requires vigilance against rust but performs adequately with proper finishing.

Coastal areas create harsh conditions where salt air attacks finishes and promotes corrosion. Wood and steel both demand more attention, while fiberglass remains unbothered by salt exposure.

Extreme temperature swings cause wood to expand and contract significantly, leading to warping and fit issues. Fiberglass and steel maintain dimensional stability regardless of temperature variations.

Making the Right Choice for Your Situation

Selecting the right door material requires honest assessment of your priorities, circumstances, and capabilities. Consider these key questions:

Budget considerations: Can you afford higher upfront costs for lower long-term maintenance, or do you need to minimize initial investment even if it means more ongoing expenses? Remember that the cheapest purchase price often proves most expensive over time.

Climate realities: What’s your local weather like year-round? Harsh conditions argue strongly for fiberglass or properly maintained steel rather than wood.

Aesthetic priorities: How important is authentic appearance versus practical durability? If you’re renovating a historic home, wood might be non-negotiable despite the maintenance. For a contemporary design, fiberglass or steel may suit the aesthetic perfectly.

DIY comfort level: Are you handy and willing to invest time in maintenance, or would you rather minimize upkeep tasks? Your honest answer should heavily influence material choice.

Architectural style plays an important role in material appropriateness. Victorian, Colonial, and Craftsman homes often look best with wood doors that match their period character. Mid-century modern and contemporary designs frequently pair well with sleek fiberglass or steel options. Mediterranean and Spanish styles can work with any material depending on finish and design details.

The decision of when to prioritize appearance versus practicality depends on the door’s location and your home’s overall design. Your main entry door makes a significant first impression and may justify choosing wood for aesthetics even with higher maintenance. Side and back doors where appearance matters less are prime candidates for practical fiberglass or steel.

Warranties factor into long-term cost planning as well. Wood doors typically offer limited warranties focused on manufacturing defects rather than material performance. Fiberglass doors from manufacturers like US Door & More Inc often come with substantial warranties covering warping, cracking, and finish integrity—sometimes 20 years or more. Steel door warranties vary widely but generally cover rust-through and structural issues. Strong warranties reduce financial risk and signal manufacturer confidence in their products’ durability.

Conclusion

There’s no universally “best” door material—the right choice depends entirely on your specific priorities and circumstances. Wood doors reward those who appreciate natural beauty and don’t mind regular maintenance with timeless elegance. Fiberglass doors serve homeowners seeking the appearance of wood combined with modern durability and minimal upkeep. Steel doors deliver maximum value for those prioritizing security, longevity, and budget-friendly practicality.

The key is making an informed decision based on total lifecycle costs rather than just initial price. A door that costs more upfront but requires minimal maintenance may prove far more economical over 20 years than a cheaper option demanding constant attention and periodic repairs. Consider your climate, evaluate your willingness to maintain the door regularly, and be honest about your priorities.

Ultimately, the right door material pays for itself through reduced headaches and expenses over time. Whether you choose the classic appeal of wood, the balanced performance of fiberglass, or the no-nonsense durability of steel, understanding what you’re committing to ensures satisfaction for decades to come. Your entry door serves your home every single day—choose wisely, and it will reward you with beauty, security, and value that lasts.