What Size Trowel for 12×24 Floor Tile?

Installing 12×24 tiles seems simple until you’re faced with confusing trowel options; choosing the wrong one can create hollow spots that crack the tiles months later.

So what size trowel for 12×24 floor tile actually works? The answer isn’t simple; your tile’s material, thickness, and location all matter.

This decision separates professional results from expensive failures, and understanding it could save you from ripping up your entire floor.

What Is Trowel Size and Why Does It Matter?

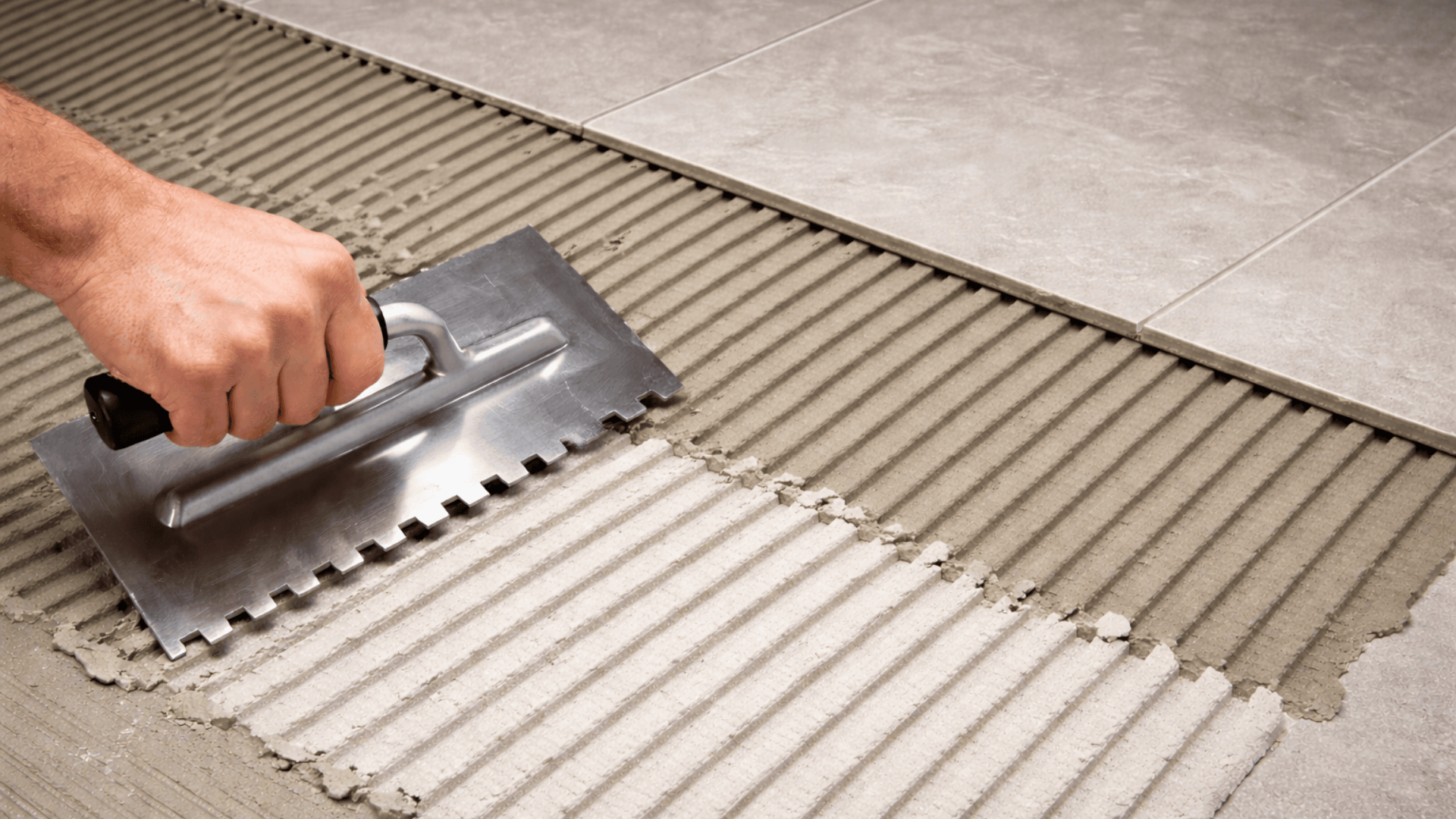

Trowel size refers to the notch dimensions, the size of the grooves cut into the trowel’s edge. These notches determine how much mortar gets spread under your tile.

Bigger notches mean more mortar, which matters because proper mortar coverage prevents loose tiles and uneven edges (called lippage).

Industry standards require 80-95% mortar coverage for strong adhesion and long-lasting results.

Using the right trowel size ensures your tiles stay flat, stick properly, and don’t crack or pop loose over time. It’s the foundation of a professional-looking tile job.

Recommended Trowel Size for 12×24 Floor Tiles

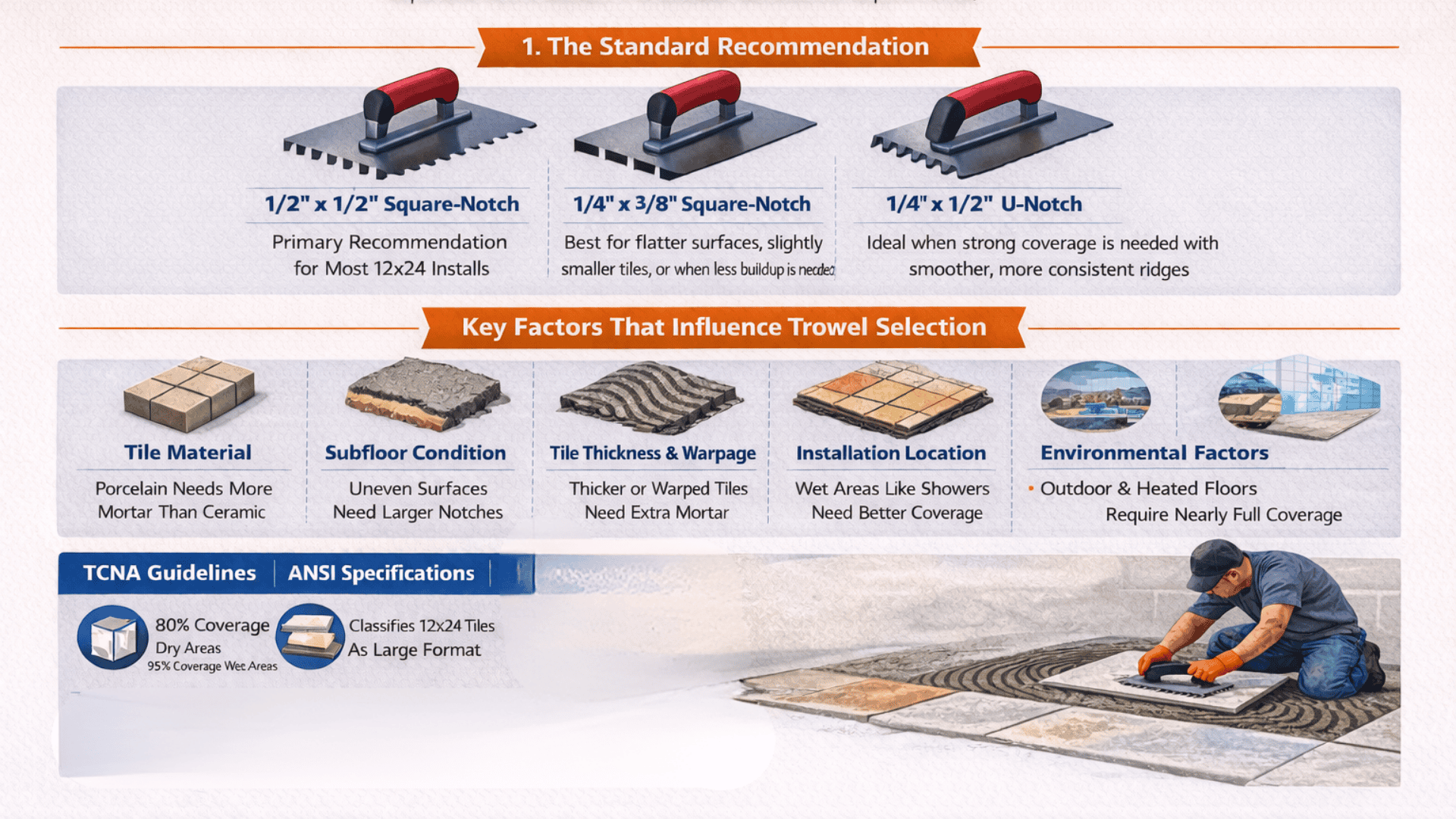

For 12×24 floor tiles, most professionals recommend a 1/2″ x 1/2″ square-notch trowel as the standard choice, though some situations may require adjustments based on tile thickness and subfloor conditions.

1. The Standard Recommendation

Choosing the right trowel notch ensures proper mortar coverage and a strong bond. Use the options below based on tile size and surface flatness.

| TROWEL TYPE | BEST USE |

|---|---|

| 1/2-inch x 1/2-inch square-notch | Primary recommendation for most floor tile installs and larger tiles. |

| 1/4-inch x 3/8-inch square-notch | Best for flatter surfaces, smaller tiles, or thinner mortar needs. |

| 1/4-inch x 1/2-inch U-notch | Use when you need strong coverage but want smoother, more even ridges. |

Factors That Influence Trowel Selection

Choosing the right trowel isn’t one-size-fits-all; several factors affect which size works best for your 12×24 tiles.

- Tile Material: Porcelain needs more mortar than ceramic for proper bonding. Natural stone often requires larger notches because its back is uneven and needs extra coverage to prevent cracking.

- Subfloor Condition: Flat subfloors work with standard sizes, but uneven surfaces need larger notches to fill low spots and create a level base for tiles.

- Tile Thickness and Warpage: Thicker or warped tiles require more mortar for full coverage. Extra mortar helps press warped tiles flat without creating hollow spots.

- Installation Location: Wet areas, such as showers, need better coverage to prevent water damage. Larger trowels ensure waterproof integrity and stop mold growth behind tiles.

- Environmental Factors: Outdoor spaces and heated floors require full coverage to manage temperature changes. Larger trowels create stronger bonds that handle expansion and contraction.

Industry Standards and Expert Recommendations

Professional tile installation follows strict guidelines to ensure quality results. Here’s what the experts and industry organizations recommend for 12×24 tiles.

- TCNA Guidelines: The Tile Council of North America requires 80% mortar coverage for dry areas and 95% for wet installations. For 12×24 tiles, they recommend medium-bed mortar and the appropriate trowel size.

- ANSI Specifications: ANSI classifies 12×24 tiles as large format, requiring specific methods. These specs mandate back-buttering in addition to troweling to ensure complete coverage and prevent failures.

- Professional Best Practices: Experienced installers recommend the “burn-in” technique, pressing tiles firmly with a twisting motion. They suggest periodically checking coverage by pulling up a tile before the mortar sets.

Types of Trowels for Tile Installation

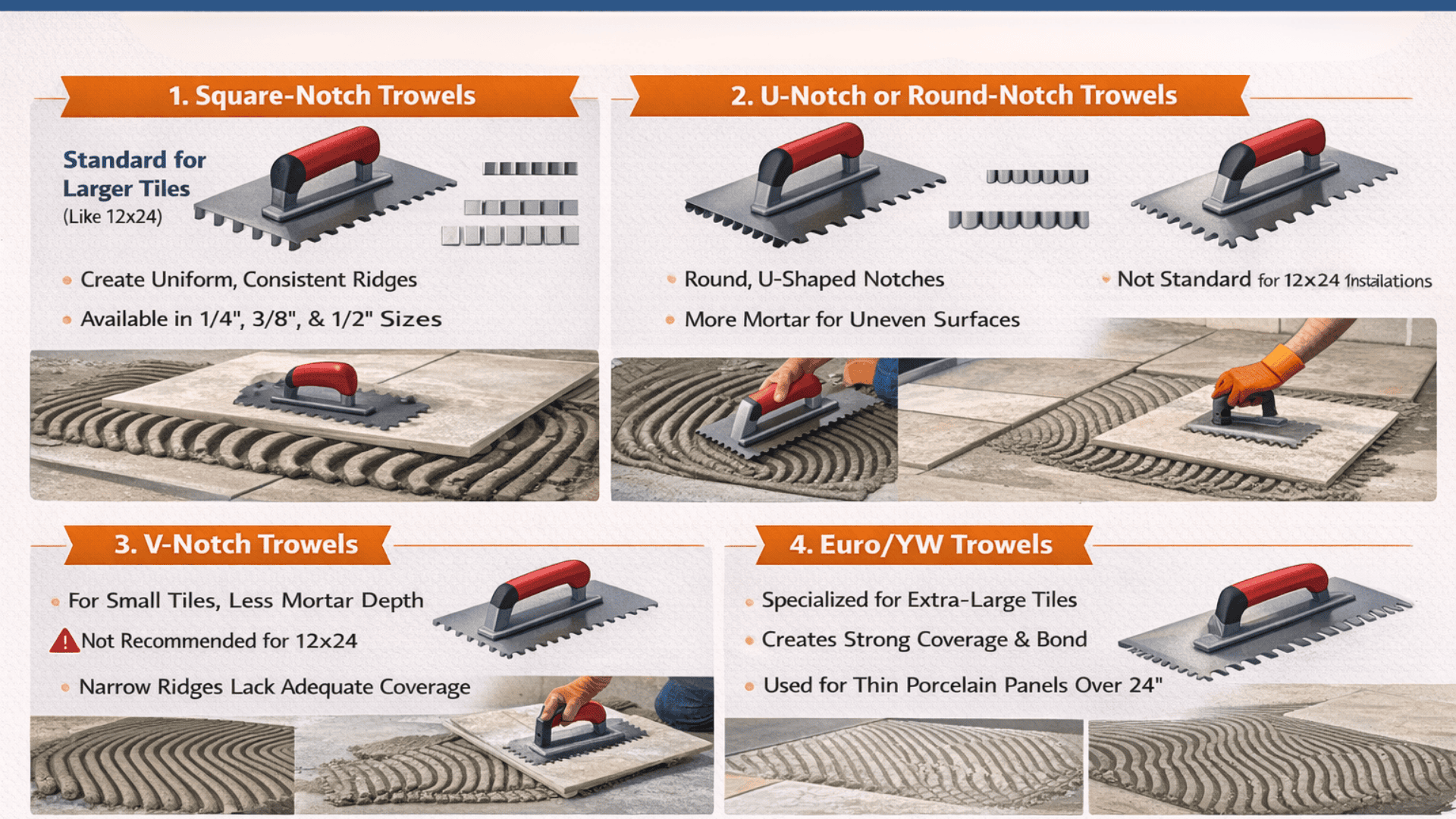

Different trowel styles create different mortar patterns, and choosing the right type matters as much as choosing the right size for your 12×24 floor tiles.

1. Square-Notch Trowels

The go-to choice for large format tiles like 12×24, square-notch trowels create uniform adhesive ridges that collapse evenly when tiles are pressed down.

Available in 1/4″, 3/8″, and 1/2″ sizes, they provide the consistent coverage needed for rectangular tiles and ensure proper mortar distribution across the entire tile back.

2. U-Notch or Round-Notch Trowels

These trowels feature rounded or U-shaped notches that deposit more mortar than square notches of the same size.

They’re useful for uneven substrates or tiles with textured backs, though square-notch remains the standard for 12×24 installations due to better ridge consistency and easier verification of coverage.

3. V-Notch Trowels

V-notch trowels work best for smaller tiles under 8×8 inches, where minimal mortar depth is needed.

They’re not recommended for 12×24 tiles because the narrow ridges don’t provide enough mortar coverage to meet industry standards or properly support the tile’s weight.

4. Euro/YW Trowels

These specialized trowels feature a unique notch pattern designed for extra-large thin porcelain panels and modern large-format tiles.

They’re a newer innovation that helps installers achieve better coverage on tiles over 24 inches, though traditional square-notch trowels remain sufficient for standard 12×24 installations.

The Importance of Back Buttering

Back buttering means applying a thin layer of mortar directly to the back of the tile before setting it. This extra step significantly improves coverage and prevents common installation failures with 12×24 tiles.

- What Back Buttering Does: It creates a skim coat on the tile back using the flat side of your trowel, filling microscopic voids and ensuring maximum contact between tile and substrate for superior adhesion.

- When It’s Required: Always back butter natural stone, warped tiles, and wet area installations. Industry standards recommend it for all large-format tiles, like 12×24, to achieve the required 95% coverage in critical areas.

- Proper Technique: Apply a thin, even layer with the trowel’s flat edge; not thick ridges. The goal is to coat the entire back surface without adding excessive thickness that could cause tiles to sit too high.

- Key Benefits: Back buttering boosts coverage from 80% to 95%, fills voids in uneven tile backs, compensates for warpage, and prevents hollow spots that lead to cracking when someone steps on the tile.

- Avoiding Mistakes: Don’t apply too much mortar or create thick buildup. A proper skim coat is thin enough to see trowel marks but thick enough to eliminate air pockets and ensure complete bonding.

Choosing the Right Mortar

Selecting the correct mortar ensures strong adhesion, proper support, and long-term durability. Tile size and substrate type both influence the best choice.

| CATEGORY | KEY POINTS |

|---|---|

| Medium Bed vs Thin Set | A medium bed is preferred for 12×24 tiles to prevent sagging and provide better support. Thin-set works well for smaller, lighter tiles. |

| Modified vs Unmodified | Modified offers a stronger bond and flexibility. Unmodified is required for certain membranes, such as Schluter or Ditra. |

| Large Format Tile Mortar | Designed for tiles 15 inches or larger. Offers anti-sag properties and improved coverage. |

Step-by-Step Installation Process for 12×24 Tiles

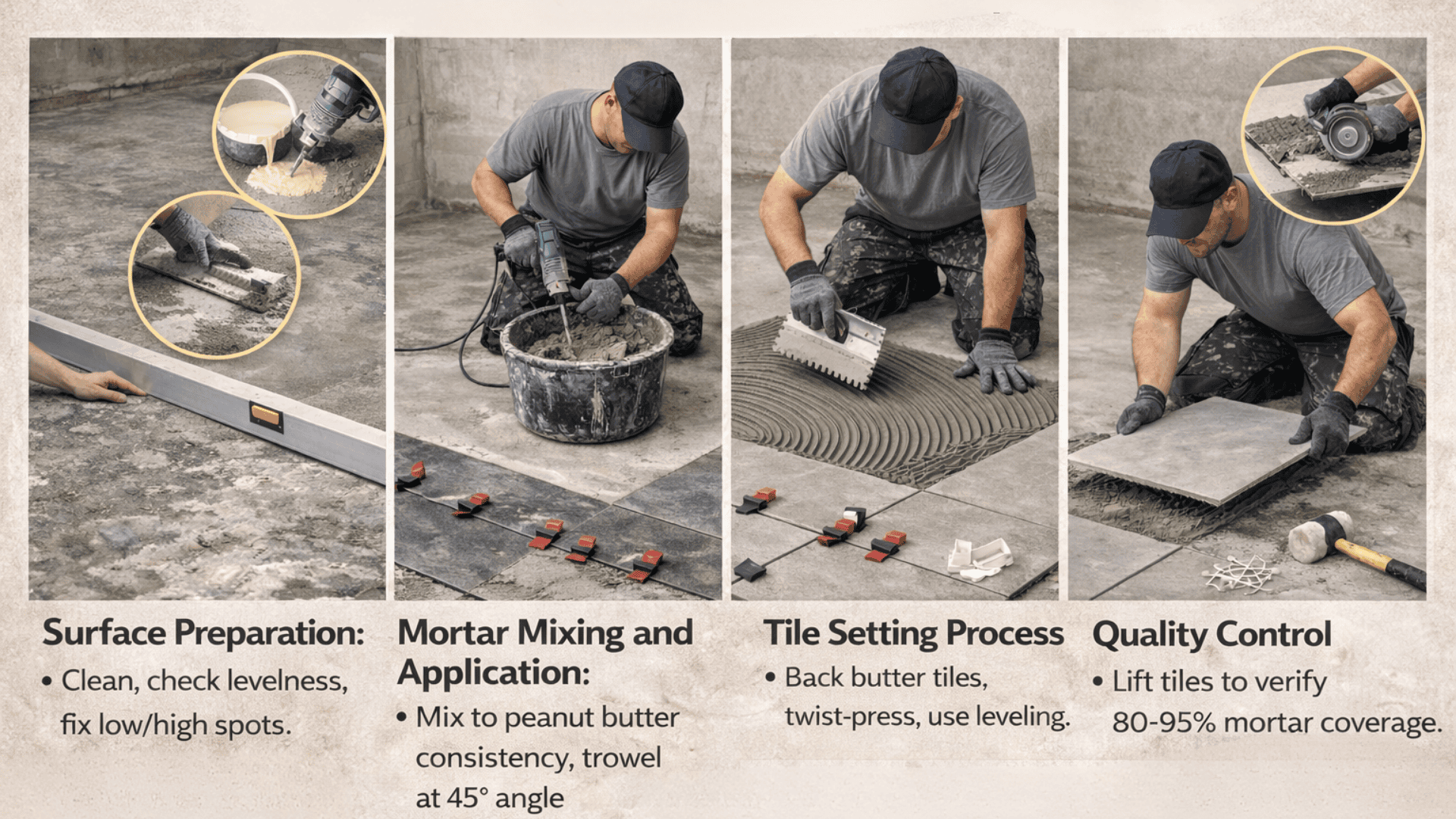

Installing 12×24 floor tiles requires careful preparation and proper technique at every stage. Follow these steps for professional results that last.

- Surface Preparation: Clean substrate thoroughly and check levelness with a straightedge. Variations beyond 1/8″ over 10 feet need fixing. Repair low spots with leveling compound and grind high points for a flat surface.

- Mortar Mixing and Application: Mix to peanut butter consistency following the manufacturer’s ratios. Hold the trowel at a 45-degree angle for uniform ridges. Apply in sections tileable within 15-20 minutes, troweling perpendicular to tile direction for better air release.

- Tile Setting Process: Back butter each tile with a thin skim coat, then place using a twist-and-press motion. Use leveling systems to prevent lippage. Maintain 1/8″ grout lines and periodically lift tiles to verify 80-95% coverage during installation.

- Avoid Common Mistakes: Never use undersized trowels or over-work mortar. Always back butter large tiles and check coverage regularly. Don’t set tiles after the mortar’s open time expires, or you’ll create weak bonds.

- Quality Control: Verify work by lifting tiles during installation to check mortar collapse and coverage patterns. This prevents cracking, lippage, or loose tiles, which would require expensive future repairs.

Tools and Materials Checklist

Using proper tools and quality materials ensures accurate alignment and long-lasting results. Keep this essentials list ready before starting installation.

| ESSENTIAL TOOLS | MATERIALS |

|---|---|

| 1/2″ x 1/2″ square-notch trowel | Medium-bed or LFT mortar |

| Margin trowel | Grout in a complementary color |

| Rubber mallet | Sealer for natural stone |

| Tile leveling system | – |

| Spacers 1/8″ or 3/16″ | – |

| Level | – |

| Grout float | – |

| Mixing paddle and drill | – |

| Tile cutter or wet saw | – |

Troubleshooting Common Issues with 12×24 Tile Installation

Even experienced installers encounter challenges when working with large-format tiles. Here’s how to identify and fix the most common problems during your installation.

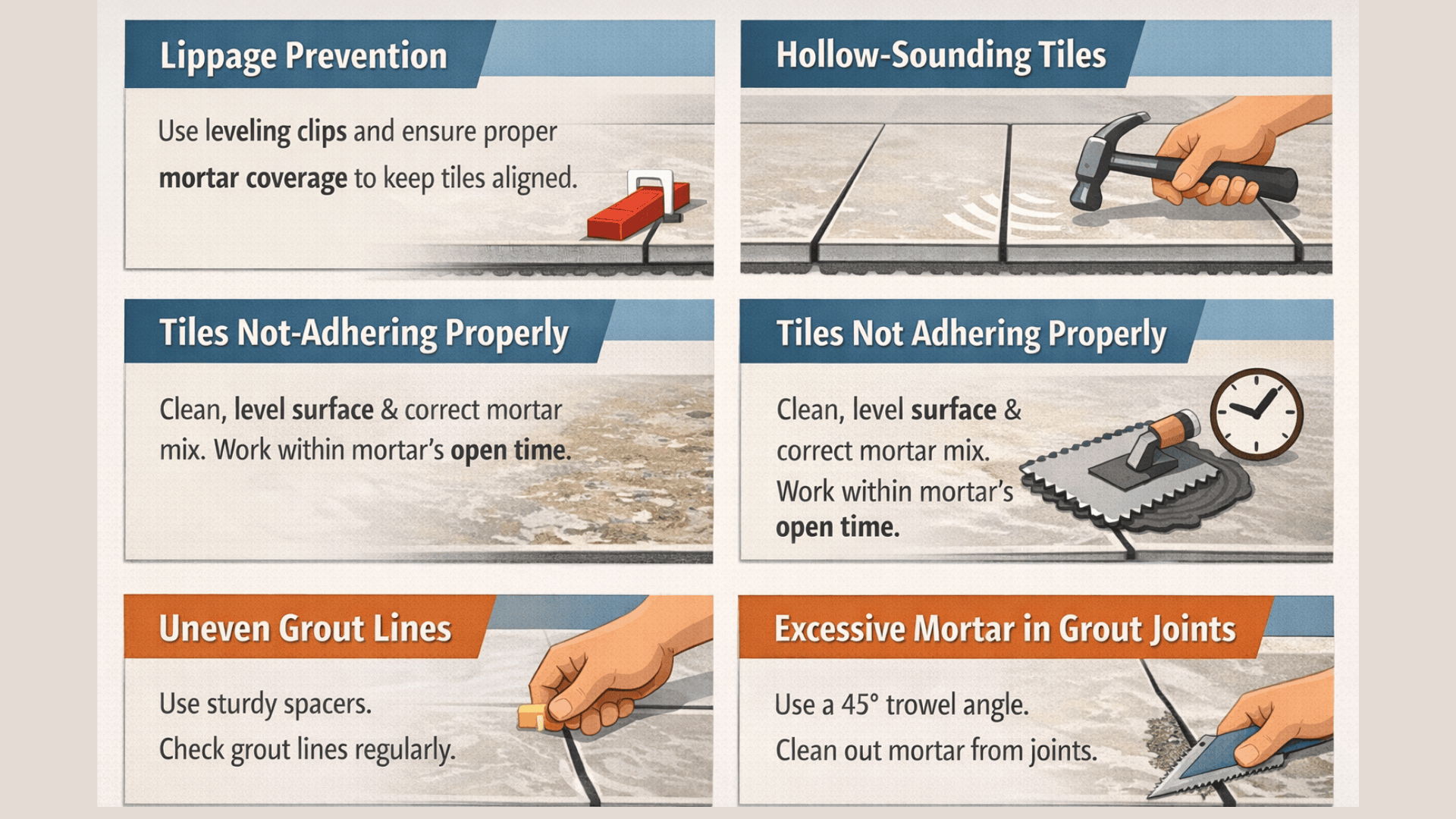

1. Lippage Prevention

Lippage occurs when tile edges don’t align, creating uneven surfaces that are both unsightly and dangerous. Use leveling systems like clips and wedges to hold tiles flat while the mortar sets, and ensure proper mortar coverage with adequate back buttering.

Maintaining a consistent trowel technique and working on a level substrate are essential for preventing this issue.

2. Hollow-Sounding Tiles

When tiles sound hollow when tapped, it indicates insufficient mortar coverage, creating voids underneath.

Before grouting, remove affected tiles, clean off old mortar, and reinstall with proper troweling and back buttering techniques. Use the tap test throughout installation; tiles should sound solid when knocked, not hollow or drum-like.

3. Tiles Not Adhering Properly

Poor adhesion usually stems from incorrect mortar consistency, contaminated surfaces, or working beyond the mortar’s open time.

Ensure your substrate is clean and dry, mix the mortar to the proper consistency, and spread only what you can tile within 15-20 minutes. If the mortar feels dry or crusty when setting tiles, scrape it off and apply fresh mortar.

4. Uneven Grout Lines

Spacers can crush under the weight of large tiles, causing grout lines to narrow or become inconsistent.

Work in manageable sections to avoid walking on freshly set tiles, and invest in quality rigid spacers designed for large-format installations. Check grout line width regularly and adjust before the mortar sets.

5. Excessive Mortar in Grout Joints

Mortar squeezing into grout joints occurs when the trowel is held at too shallow an angle or when too much pressure is applied.

Maintain a consistent 45-degree trowel angle and clean excess mortar from joints immediately using a margin trowel or grout saw. Prevention is easier than removal; proper troweling technique keeps joints clean from the start.

Pro Tips from Professional Installers

Learning from experienced tile setters can save you time, money, and frustration. Here are insider secrets that professionals use to achieve flawless 12×24 tile installations every time.

- Test Coverage Throughout: Periodically lift tiles during installation to verify 80-95% mortar contact. This prevents the discovery of hollow spots after grouting, when fixes become expensive and time-consuming.

- Respect Open Time: Work in sections that can be completed within 15-20 minutes before the mortar skins over. Hot, dry conditions reduce open time while cool, humid weather extends it.

- Plan Your Layout First: Dry-lay tiles before mixing mortar to avoid awkward cuts in visible areas. Proper planning ensures balanced borders and minimizes wasted material from poor cuts.

- Account for Warpage: Order 10-15% extra tiles for potential warpage, breakage, and future repairs. Inspect and reject severely bowed tiles before installation to prevent lippage issues.

- Maintain Clean Tools: Scrape dried mortar off trowels immediately and rinse frequently. Clean notches create consistent ridges while dirty tools produce uneven coverage that weakens bonds.

Wrapping It Up

Now you know what size trowel to use for 12×24 floor tile installations: typically 1/2″ x 1/2″ square-notch, but adjustable based on your tile and conditions.

Remember to back butter, check coverage by lifting tiles, and maintain proper technique throughout.

The right trowel, combined with proper installation methods, prevents cracking, lippage, and costly repairs. Take your time, follow these guidelines, and you’ll achieve professional results that last for decades.