All Types of Sanders and How to Choose One

Starting a woodworking project and confused by all the different sanders? You’re not alone. With so many types available, picking the right one feels overwhelming.

The reality is that each sander serves a specific purpose. Using the right one means smooth, professional results.

Using the wrong one wastes time and damages surfaces.

This blog explains what sanders do, the types of sanders, and helps you choose the right tool for your project.

What Is a Sander and Why Are There So Many Types

A sander is a power tool designed to smooth surfaces by abrading them with sandpaper or abrasive materials.

It removes old finishes, evens out rough spots, and prepares surfaces for painting or staining.

Sanders work faster and more efficiently than manual sanding, saving you time and reducing physical strain.

Different projects need different sanders because:

- Surface types vary: Flat surfaces need different tools than curves or corners

- Project scales differ: Small crafts need compact sanders, large jobs need powerful ones

- Finish quality matters: Some projects need rough sanding, others need smooth finishes

Main Categories of Sanders

There are two main types of sanders based on category and how they operate: power sanders and hand sanders.

Power Sanders

Power sanders use electricity, batteries, or compressed air to automate the sanding process.

They work faster and require less physical effort than manual sanding.

A motor moves the sandpaper in specific patterns to smooth surfaces efficiently, making them ideal for large projects and heavy material removal.

Hand Sanders

Hand sanders rely on manual effort to move the abrasive material across surfaces. They offer more control and precision for detailed work, small areas, and delicate projects.

They’re simpler tools that hold sandpaper in place while you provide the sanding motion, perfect for touch-ups and fine finishing work.

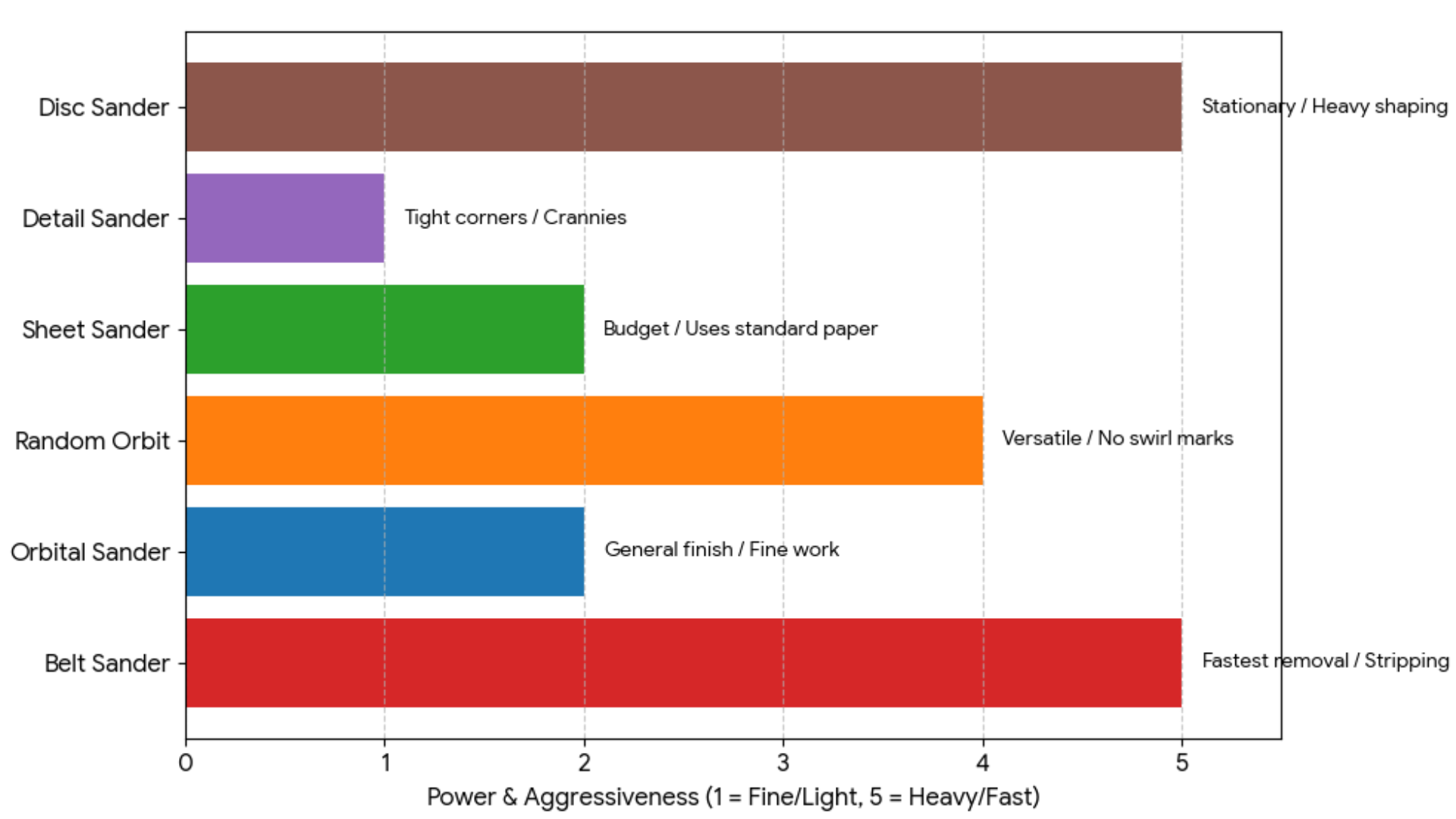

Types of Power Sanders and Their Uses

Power sanders come in various types, each designed for specific tasks. Here’s a breakdown of all common power sanders and their characteristics.

1. Belt Sander

Belt sanders use a continuous loop of sandpaper moving around two drums. They’re the most aggressive power sanders for heavy material removal.

Key Characteristics:

- Most aggressive material removal

- Moves in a straight linear direction

- Best for large flat surfaces

2. Orbital Sander

Orbital sanders move sandpaper in small circular patterns while vibrating. They balance speed with smoothness for versatile sanding.

Key Characteristics:

- Dual-action motion (circular + vibration)

- Moderate material removal

3. Detail Sander

Detail sanders feature triangular or pointed pads for tight spaces. Their specialized shape reaches where larger sanders can’t fit.

Key Characteristics:

- Triangular or pointed pad

- Reaches corners and edges

- Essential for intricate woodwork

4. Sheet Sander

Sheet sanders use standard sandpaper on a rectangular vibrating pad. They provide the gentlest smoothing action.

Key Characteristics:

- Vibrates in straight lines

- Minimal material removal

- Best for final smoothing

5. Disc Sander

Disc sanders use circular discs spinning in one direction. They’re aggressive but with less coverage than belt sanders.

Key Characteristics:

- Spins continuously

- Aggressive material removal

6. Drywall Sander

Long-handled sanders are designed for smoothing drywall and ceiling surfaces. They feature extendable poles for reaching high areas without ladders.

Key Characteristics:

- Extended reach for walls and ceilings

- Lightweight with dust collection

- Specifically for drywall compound smoothing

7. Drum Sander

Large stationary or handheld sanders with a rotating cylindrical drum. Used for heavy-duty floor refinishing and thickness planing.

Key Characteristics:

- Cylindrical rotating drum

- Professional floor refinishing tool

8. Edge Sander

Specialized sanders are designed for sanding along edges, baseboards, and tight spots near walls. Common in floor refinishing.

Key Characteristics:

- Works perpendicular to surfaces

- Reaches edges and corners

- Complements drum sanders

9. Spindle Sander

Features a spinning cylindrical spindle that oscillates up and down. Perfect for sanding curved edges and contoured surfaces.

Key Characteristics:

- Spinning oscillating spindle

- Sands’ curved and contoured edges

10. File Sander (Belt File)

Narrow belt sanders resemble a file shape. Used for detailed work, sharpening, and reaching into grooves.

Key Characteristics:

- Narrow belt design

- Reaches grooves and tight spots

- Precision detail work

Types of Hand Sanders

Hand sanders rely on manual effort to smooth surfaces. Here’s a breakdown of all common hand sanders and their characteristics.

11. Sanding Block

Sanding blocks are rectangular blocks wrapped with sandpaper for flat surface sanding. They provide even pressure distribution and a comfortable grip for manual sanding.

Key Characteristics:

- Rectangular block design

- Even pressure distribution

12. Sanding Sponge

Sanding sponges are flexible foam blocks coated with abrasive material. They conform to curved and contoured surfaces easily.

Key Characteristics:

- Flexible foam construction

- Conforms to curves and contours

- Available in various grit levels

13. Hand-Held Sander

Handheld sanders are simple holders that clamp sandpaper sheets. They provide a comfortable grip for manual sanding work.

Key Characteristics:

- Clamps standard sandpaper sheets

- Comfortable ergonomic grip

- Versatile for general sanding

14. Contour Sander

Contour sanders feature curved or shaped profiles that match specific contours. They’re designed for sanding rounded edges and molded surfaces.

Key Characteristics:

- Curved or profiled shapes

- Matches specific contours

15. Corner Sander

Corner sanders have angled or triangular designs for reaching into corners. They access tight 90-degree angles that flat blocks can’t reach.

Key Characteristics:

- Angled or triangular design

- Reaches tight corners

- Essential for detailed edge work

16. Profile Sander

Profile sanders comes with interchangeable shaped pads that match different profiles. They handle various molding shapes and decorative details.

Key Characteristics:

- Interchangeable shaped pads

- Matches various profiles

- Handles decorative moldings

17. Sandpaper Sheets

Plain sandpaper sheets without holders for direct hand sanding. They’re the most basic and flexible option for manual sanding.

Key Characteristics:

- No holder required

- Economical basic option

Power Sanders vs. Hand Sanders: Which Should You Use?

Choosing between power sanders and hand sanders depends on your project size, surface type, and finish requirements.

Here’s a comparison to help you decide.

| Factor | Power Sanders | Hand Sanders |

|---|---|---|

| Best For | Large surfaces, heavy removal | Small projects, detail work |

| Speed | Fast, saves time | Slower, time-consuming |

| Physical Effort | Minimal effort | More demanding |

| Control | Less precise | Complete control |

| Cost | Higher investment | Inexpensive |

| Power Requirement | Needs electricity/batteries | No power needed |

| Surface Damage Risk | Can over-sand | Minimal risk |

| Noise Level | Louder | Quieter |

| Skill Level | Requires practice | More forgiving |

How to Choose the Right Sander for Your Project

Choose Power Sanders When:

- Working on large surface areas

- Need quick material removal

- Want consistent results

Choose Hand Sanders When:

- Working on small projects

- Need precise control

- The budget is limited

Use power sanders for rough work and large areas, then finish with hand sanders for details and final smoothing.

Common Mistakes When Choosing or Using a Sander

1. Using the wrong type of sander

Fix: Match the sander to the task (heavy removal, general sanding, or finishing).

2. Confusing orbital, palm, and random orbital sanders

Fix: Use a random orbital sander for the most versatility and smoother results.

3. Applying too much pressure

Fix: Let the sander’s weight do the work.

4. Skipping sandpaper grits

Fix: Progress gradually through grit instead of jumping too fast.

5. Ignoring dust collection and safety

Fix: Use dust extraction and wear proper safety gear.

6. Using a power sander for delicate areas

Fix: Switch to a hand sander for edges, corners, and final touch-ups.

7. Expecting one sander to do every job

Fix: Combine power and hand sanders for best results.

Conclusion

There are many types of sanders because different projects need different tools.

Power sanders handle large surfaces quickly, while hand sanders provide precision for delicate work. Belt sanders strip finishes, random orbital sanders create smooth surfaces, and detail sanders reach tight corners.

Match your sander to your task by considering project size and surface type.

For best results, use power sanders for heavy work and hand sanders for final touches. With the right sander, you’ll achieve professional results every time.