Metal Panels vs. Drywall: The Ultimate Durability Showdown

When planning a high-end residential or commercial project, the choice of wall materials can significantly impact both aesthetics and long-term performance. Two popular options dominate the market: traditional drywall and increasingly popular metal panels. While drywall has been the construction industry standard for decades, metal panels are gaining traction among architects and property owners who prioritize durability and modern design.

This decision goes beyond simple preference. The material you choose affects everything from installation timelines and maintenance requirements to structural integrity and lifecycle costs. Metal panels promise superior strength and resistance to common problems like moisture damage and impact, while drywall offers familiarity, easier installation, and lower upfront costs. Understanding the real-world performance differences between these materials is essential for making an informed investment. Whether you’re developing luxury condominiums, upscale office spaces, or premium retail environments, the durability showdown between metal panels and drywall deserves careful consideration before breaking ground on your next project.

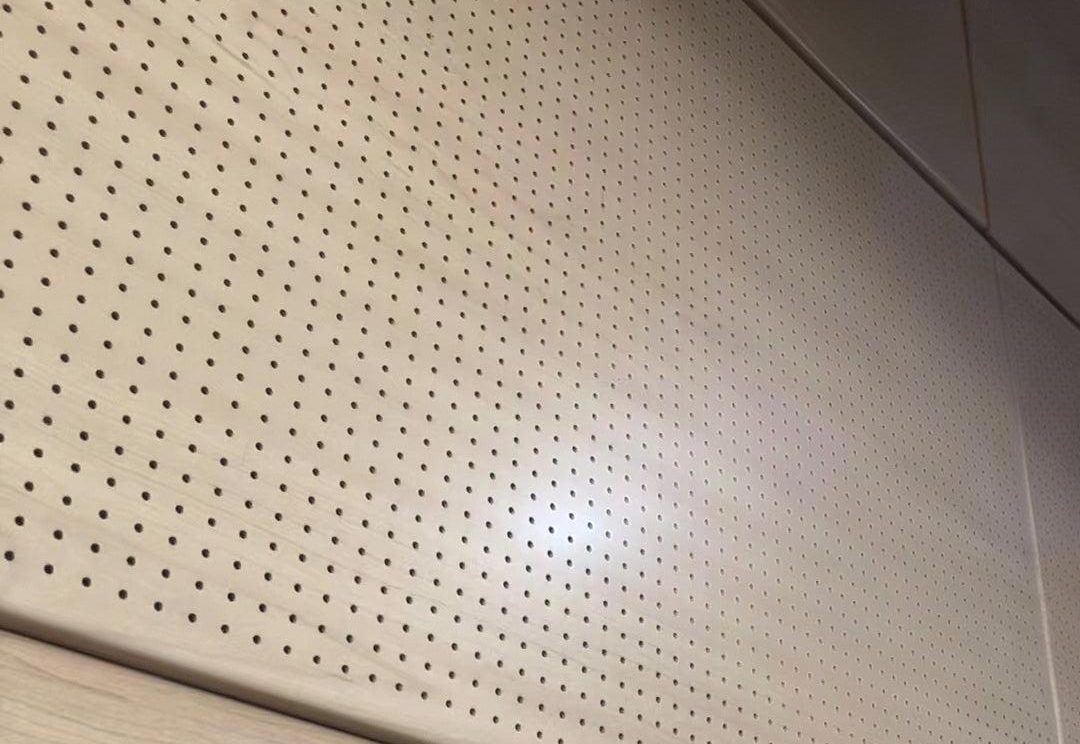

Introduction to Metal Panels

Metal panels represent a modern evolution in interior wall systems, constructed primarily from aluminum, steel, or zinc alloys that deliver exceptional structural performance. These engineered surfaces come in various finishes—from brushed and polished metals to powder-coated options in virtually any color—allowing designers to achieve both industrial chic and refined elegance. The manufacturing process involves precision forming techniques that create panels with consistent thickness and dimensional stability, ensuring seamless installation across large wall expanses.

The appeal of metal panels extends far beyond their striking visual presence. Their inherent strength makes them virtually impervious to the warping, sagging, and deterioration that plague traditional materials over time. In high-traffic commercial environments like upscale hotels or corporate lobbies, metal panels withstand daily wear without showing age. They resist moisture penetration completely, eliminating concerns about mold growth or water damage that can compromise building envelopes. Fire resistance is another significant advantage, as metal panels are non-combustible and help contain flames rather than fuel them. For architects and developers focused on creating spaces that maintain their premium appearance decades into the future, metal panels offer a compelling combination of aesthetic versatility and uncompromising resilience that justifies their position as a premium wall solution.

Introduction to Drywall

Drywall, also known as gypsum board or sheetrock, has served as the backbone of interior construction since the mid-20th century. Composed of a gypsum plaster core sandwiched between thick paper facings, these standardized panels offer an economical and versatile solution for creating smooth interior surfaces. The material’s widespread adoption stems from its ease of installation, requiring only basic cutting tools and joint compound to achieve finished walls. Contractors appreciate the straightforward process of hanging, taping, and finishing drywall, which translates to faster project completion and lower labor costs compared to more specialized wall systems.

Beyond affordability, drywall brings several practical advantages to construction projects. The material provides excellent sound dampening properties, reducing noise transmission between rooms—a valuable feature in residential settings and office environments. Gypsum’s natural fire-resistant qualities offer passive protection, as the water content within the material helps slow flame spread during fire events. Drywall also accommodates easy repairs and modifications; damaged sections can be patched or replaced without specialized skills, and running new electrical or plumbing lines through walls remains straightforward. The smooth, paintable surface accepts virtually any finish, from textured treatments to high-gloss paints, giving designers flexibility in achieving their vision. For projects where budget constraints are paramount and traditional aesthetics are preferred, drywall continues to deliver reliable performance that has made it the default choice across countless residential and commercial applications.

Durability Comparison

When evaluating structural resilience, metal panels demonstrate clear superiority in resisting physical impact. A forceful blow from moving equipment or accidental collision that would puncture drywall typically leaves metal panels unscathed or with minor surface dents that don’t compromise integrity. In commercial settings like retail spaces or healthcare facilities where carts, gurneys, and equipment constantly move through corridors, metal panels maintain their appearance and structural soundness while drywall requires frequent patching and repainting. The difference becomes particularly evident in high-traffic zones where even reinforced drywall eventually succumbs to repeated stress, developing cracks around corners and doorways that metal installations simply don’t experience.

Moisture resistance separates these materials dramatically. Drywall’s paper facing and gypsum core absorb water readily, leading to swelling, disintegration, and mold growth when exposed to humidity or direct water contact. Even moisture-resistant “green board” variants offer only limited protection and will fail under sustained exposure. Metal panels, conversely, provide absolute moisture immunity—water beads off their surface without penetration, making them ideal for humid environments like spas, indoor pools, or coastal properties where salt air accelerates material degradation. This characteristic eliminates the costly remediation projects that plague drywall installations in moisture-prone areas. Manufacturers like AnsusMetal, known for their metal fabrication expertise in architectural applications, have demonstrated that properly engineered metal systems can withstand even the most demanding environmental conditions.

Temperature fluctuations and environmental stress reveal another durability gap. Drywall expands and contracts with humidity changes, creating the hairline cracks and nail pops that require periodic repair in buildings experiencing seasonal climate variations. Metal panels maintain dimensional stability across temperature ranges, with properly engineered fastening systems accommodating thermal expansion without visible distortion. Fire performance further distinguishes these materials—while both offer fire resistance, metal panels won’t contribute fuel to flames or release toxic smoke as drywall’s paper facing can during combustion. The longevity difference manifests clearly over decades: properly installed metal panels can perform flawlessly for fifty years or more with minimal maintenance, while drywall typically requires significant repairs or replacement within twenty to thirty years, even under ideal conditions. This extended service life makes metal panels particularly valuable in institutional settings where renovation disruptions carry substantial operational costs.

Long-term Value vs. Initial Costs

The upfront cost difference between metal panels and drywall is substantial and often the primary factor driving material selection. Drywall installation typically costs between $1.50 to $3.00 per square foot for materials and labor, making it the economical choice for budget-conscious projects. Metal panel systems, by contrast, range from $15 to $40 per square foot depending on finish quality and complexity, representing a five to ten-fold increase in initial investment. This price gap understandably makes developers hesitate, particularly when facing tight construction budgets or speculative projects where immediate cost control takes priority over long-term performance.

However, lifecycle cost analysis reveals a different financial picture. Drywall’s lower entry price comes with hidden ongoing expenses that accumulate relentlessly over time. Routine repairs for cracks, dents, and water damage typically require attention every three to five years in commercial environments, with each repair cycle costing thousands of dollars in materials, labor, and business disruption. Repainting needs arise every seven to ten years as surfaces show wear, adding further expense. Metal panels eliminate virtually all these recurring costs—a simple occasional cleaning maintains their appearance indefinitely, with no patching, repainting, or section replacements needed under normal conditions.

The durability premium becomes financially justified when projects extend beyond a fifteen-year horizon. A building owner planning to hold a property for thirty years will spend more maintaining drywall through multiple repair and refinishing cycles than the incremental cost of installing metal panels initially. Insurance considerations also factor into the equation, as metal’s superior fire resistance and moisture immunity can reduce premiums and minimize catastrophic loss potential. For institutional clients like universities, hospitals, or government facilities planning for multi-decade facility lifecycles, metal panels deliver measurable return on investment through reduced maintenance budgets and extended replacement intervals that preserve capital for other priorities.

Maintenance Needs

Metal panels deliver exceptional convenience for luxury applications through their virtually maintenance-free performance. Routine care requires nothing more than periodic cleaning with mild soap and water to remove dust and fingerprints, a task that takes minutes and requires no specialized products or expertise. Unlike materials that demand careful handling, metal surfaces withstand standard commercial cleaning protocols without degradation—even high-traffic lobbies in premium office towers maintain their pristine appearance with simple quarterly cleanings. Scratches and scuffs that would permanently mar other surfaces can often be buffed out of metal panels, and powder-coated finishes resist fading from UV exposure, eliminating the need for protective treatments or refinishing cycles that disrupt building operations.

Drywall maintenance in luxury settings presents ongoing challenges that conflict with the seamless experience high-end clients expect. Touch-up painting becomes necessary whenever scuffs, scratches, or marks appear—a frequent occurrence in active environments. Matching existing paint colors precisely proves difficult as original finishes age and fade, often requiring entire wall repainting to avoid visible patches. Humidity-related issues demand vigilance, with property managers needing to monitor for early signs of water damage or mold growth that can quickly escalate into expensive remediation projects. Corner guards and protective barriers, while functional, detract from refined aesthetics that luxury properties strive to maintain.

The maintenance advantage of metal panels translates directly to operational benefits for premium properties. Reduced downtime means fewer service disruptions for tenants or guests, preserving the uninterrupted experience that distinguishes luxury environments. Lower ongoing labor costs free facility management budgets for value-adding services rather than repetitive repairs. For hospitality properties where appearance directly impacts guest satisfaction and brand reputation, interior decorative metal wall panels ensure that walls maintain their showroom condition year after year without the constant attention drywall demands, allowing staff to focus on guest services rather than building maintenance.

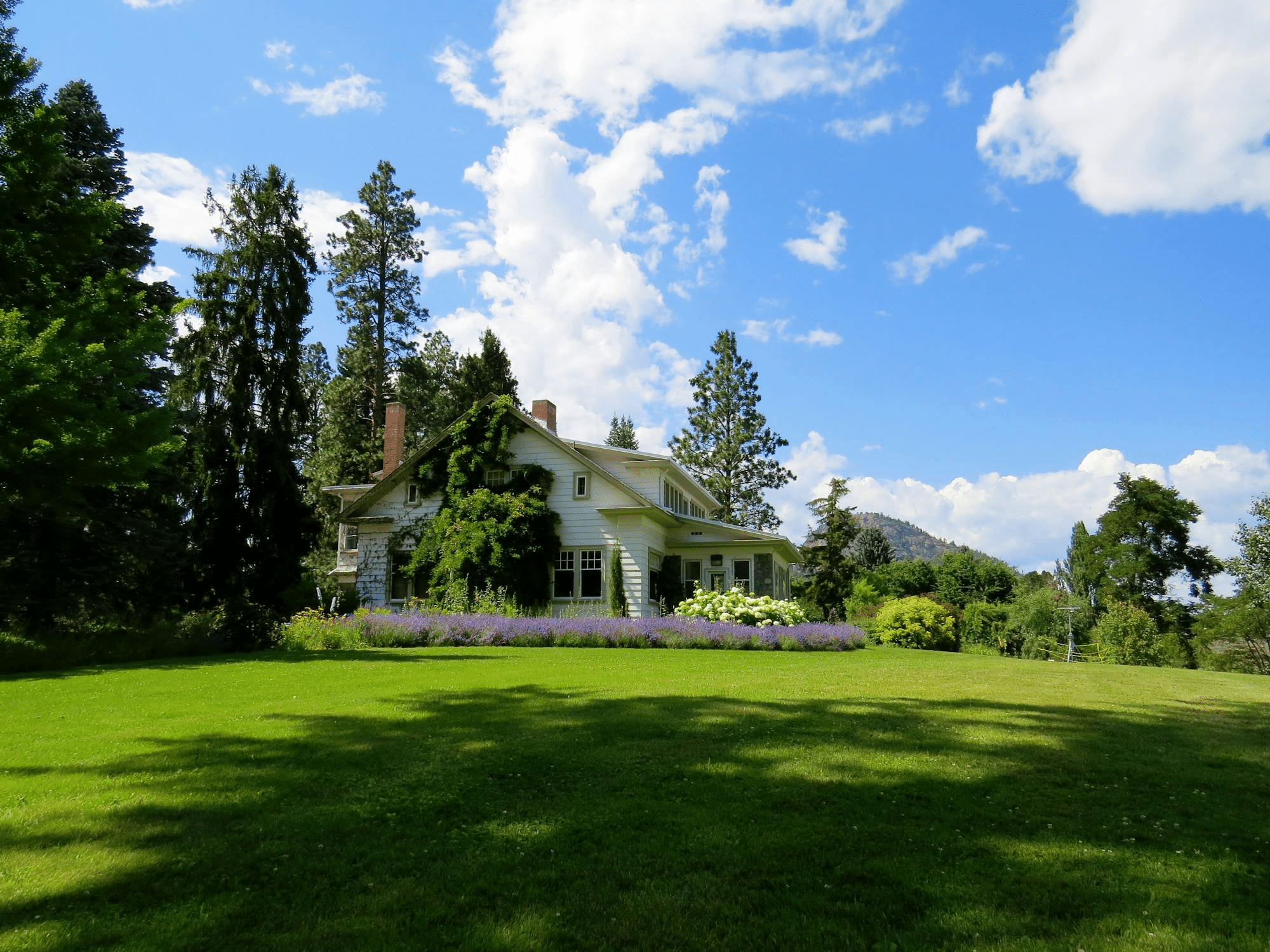

Making the Right Choice for Your Project

The durability showdown between metal panels and drywall reveals distinct advantages for each material depending on project priorities. Drywall remains the practical choice for budget-sensitive developments where immediate cost control outweighs long-term performance considerations, offering familiar installation processes and adequate functionality for standard applications. However, for luxury residential and commercial properties where longevity, minimal maintenance, and sustained premium appearance justify higher initial investment, metal panels emerge as the clear winner. Their superior resistance to impact, moisture, and environmental stress eliminates the recurring repair cycles that plague drywall installations, while their virtually maintenance-free performance preserves both aesthetics and operational budgets over decades of service. Property owners planning extended hold periods will find that metal panels deliver measurable return on investment through reduced lifecycle costs and enhanced property value. The decision ultimately hinges on your project timeline and quality expectations—if you’re building for lasting excellence rather than immediate economy, metal panels provide the durability and performance that distinguish truly premium spaces from ordinary construction.