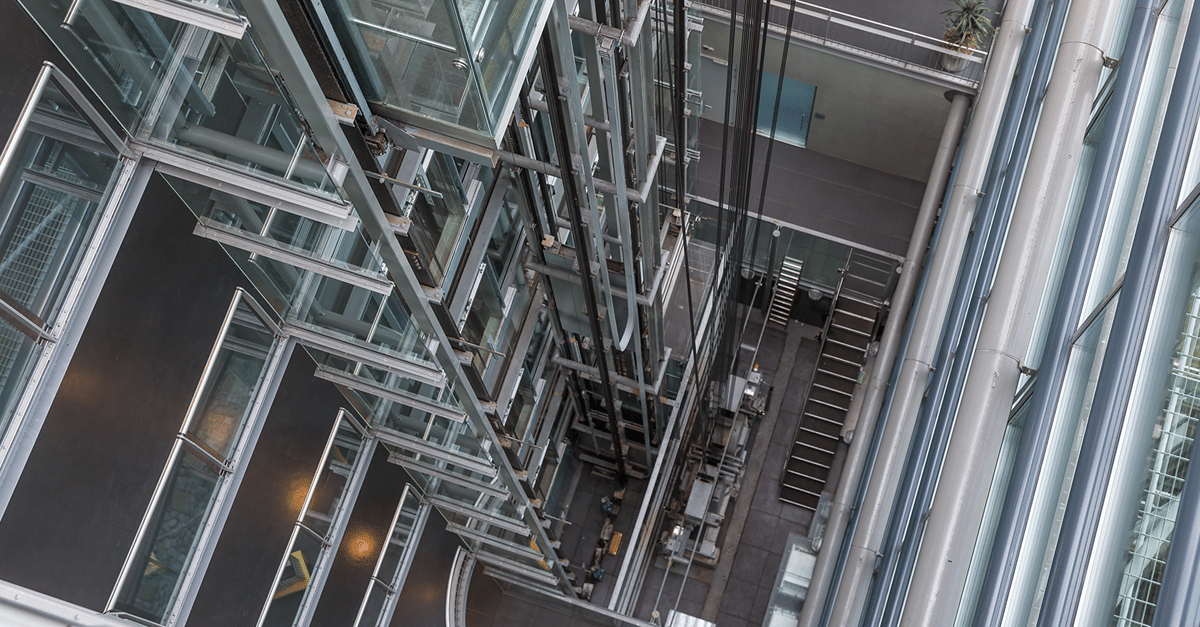

Maintaining elevators in uniquely designed buildings poses challenges. From sourcing parts to meeting safety codes, caring for these one-of-a-kind elevators requires creative solutions.

In this post, I’ll be discussing the key difficulties in maintaining these custom elevators, including unique design factors, safety standards and compliance, and integrating new technologies.

Let’s examine how to meet the maintenance challenges of unconventional elevator designs.

Key Challenges in Maintaining Custom-Designed Elevators

Unique Design Parameters:

In buildings with unique designs, elevators often have special sizes, and shapes, or are made from unusual materials. This means they need a different kind of care than regular elevators.

To keep these elevators working well, maintenance teams must use special methods and really understand these unique features.

This could involve more creative troubleshooting and a flexible approach to problem-solving, much like tailoring a service to fit a one-of-a-kind item.

Sourcing Specialized Parts and Tools:

A big issue with these unique elevators is finding the right parts and tools to fix them. Since they’re not like most elevators, their parts aren’t always easy to get. This can make fixing them take longer and cost more, which can slow down how the whole building works.

It’s similar to trying to find a rare part for an old, rare car – it takes time and can be expensive.

Sometimes, it might even mean having parts custom-made, which adds to the complexity and expense.

Technical and Engineering Complexities:

Working on these elevators requires more advanced skills than normal elevators. This is especially true for older elevators in these special buildings. Updating them or making changes needs a good mix of knowledge about old and new elevator technologies.

It’s like needing to know both how to fix a vintage car and a modern electric car.

Technicians often need to be more adaptable and resourceful, combining traditional techniques with modern solutions to effectively maintain these unique systems.

Safety Standards and Compliance in Elevator Maintenance

Making Elevators Safe in Special Buildings:

Keeping elevators safe is important, especially in buildings that have a unique design. These kinds of elevators often need special attention to make sure they’re safe because they’re not like regular elevators.

We need to work out the best ways to keep these elevators safe so that everyone who uses them, from kids to adults, feels secure.

Following the Rules for Elevator Safety:

Besides making sure elevators are safe, it’s also key to follow certain laws, like the Americans with Disabilities Act (ADA) and the rules set by local building codes. Not sticking to these rules can cause big issues, like having to pay fines or even stopping the use of the elevators.

It’s crucial to regularly check these unique elevators to ensure they’re easy and safe for everyone to use, including people with disabilities.

This means keeping up with any changes in the safety rules and making sure the elevators always meet these standards.

Technological Integration in Elevator Maintenance

Emerging Technologies in Maintenance:

Elevator maintenance is getting a high-tech makeover. Technologies like Artificial Intelligence (AI), the Internet of Things (IoT), and predictive maintenance are stepping in. What does this mean? AI helps us understand how elevators work and find problems.

IoT connects elevators to the internet, so they can send information about how they’re working in real time. Predictive maintenance uses this information to fix things before they break.

These tools help us spot and solve problems quickly and keep elevators running smoothly.

Benefits and Challenges of Technological Integration:

These new tech tools are great for a few reasons. They make fixing elevators faster and can stop problems before they start, which makes elevators safer. But, it’s not all easy. Adding these technologies to older elevators can be tricky and expensive.

It’s not just about buying new gadgets – it’s about making them work with what’s already there. This takes careful planning and sometimes big changes to the way elevators are looked after.

Best Practices for Effective Maintenance

1. Stay Ahead with Proactive Maintenance:

Regular check-ups and quick fixes are key. It’s like keeping an eye on things and fixing them before they get worse. This approach helps catch small problems early, saving time and money in the long run.

By setting a schedule for regular checks, you can keep elevators running smoothly and safely. Frequent maintenance not only identifies issues early but also extends the life of the elevator, ensuring it operates efficiently for a longer period.

2. Train Your Team Well:

The team maintaining the elevators is super important. Making sure they know what they’re doing and keeping them up-to-date with new training is crucial. This way, they’re always ready to tackle any unique problems these special elevators might have.

Regular training makes sure they’re on top of the latest elevator tech and repair techniques.

An adept team can also adapt quickly to evolving technologies and maintenance practices, enhancing the reliability of the elevator service.

3. Work with Elevator Maintenance Pros:

Sometimes, it’s best to team up with the best elevator repair service who knows all about these unique elevators. Specialists have special skills and tools that you might not have.

Working with them means better care for your elevators because they know exactly what these unique systems need.

This partnership brings in their expert knowledge and special tools, making sure your elevators are in the best hands.

These experts can also provide insights into innovative maintenance solutions and offer advice on long-term care and upgrades, ensuring the elevators remain state-of-the-art.

Conclusion:

In conclusion, maintaining elevators in uniquely designed buildings requires creative, flexible approaches to overcome challenges like sourcing parts, following safety codes, and integrating new technologies. The key is understanding these elevators’ specialized maintenance needs.

With the right plan in place, even the most unconventional designs can operate smoothly and safely for many years. Successful maintenance of these distinctive systems comes down to learning to effectively meet their unique challenges head-on.