Imagine creating stunning multicolor masterpieces with just a few clicks. The future of 3D printing is evolving rapidly, and with the advent of Automated Material Switching (AMS), the possibilities seem endless. AMS technology allows seamless transitions between different materials and colors, making intricate designs more accessible than ever.

What is AMS (Automatic Material System)?

The Automatic Material System (AMS) is an innovation in 3D printing that automates the process of switching between different materials and colors. It’s especially useful for creating intricate multicolor designs.

Definition and Functionality

AMS, built into AMS 3D printers, manages and coordinates multiple filament inputs. It uses sensors and software to switch between filaments seamlessly during the print process.

This tech supports specific design needs, like creating gradients in prints. In my experience, using an AMS 3D printer for a project allowed me to produce a detailed model with complex color transitions without manual intervention.

AMS Functions and Workflow

Automatic Filament Management

The AMS system streamlines 3D printing by automatically loading and unloading filaments, reducing manual intervention. It ensures smooth transitions between different materials, supporting complex, multi-material prints efficiently. This functionality enhances the overall printing process, making it more reliable and user-friendly.

Multi-Material Support

AMS supports multiple filaments simultaneously, enabling complex prints with various materials without manual changes. This enhances efficiency and allows for intricate designs, improving the overall printing process by automating material transitions.

Real-Time Monitoring and Control

The system tracks filament usage in real-time, providing alerts and updates to maintain optimal print quality and prevent shortages. This feature ensures smooth operations by monitoring material levels continuously, helping users manage their printing process efficiently.

Benefits of Using AMS for Multicolor Printing

AMS offers several advantages for multicolor printing:

- Efficiency: Saves time by automating filament changes.

- Precision: Reduces human error in switching filaments.

- Quality: Produces smooth color transitions.

These benefits combine to enhance the printing process, making AMS 3D printers an ideal tool for creating multicolor masterpieces.

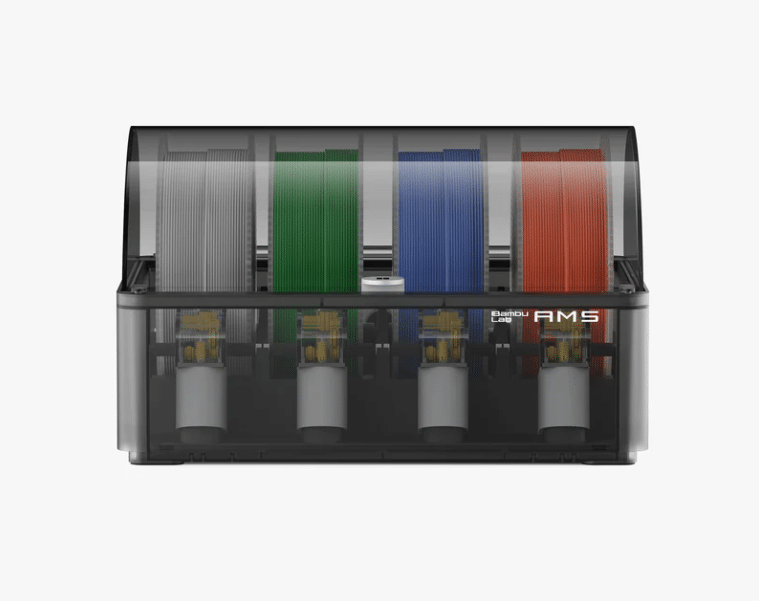

Bambu Lab’s Multicolor 3D Printing with AMS

Bambu Lab’s AMS 3D printer revolutionizes the way I create multicolor models. The automatic material switching system detects filament types and seamlessly changes to the desired color without halting the process. Once, I printed a complex multicolor model with four different shades.

The printer switched between filaments so smoothly that it felt like magic to watch the masterpiece come to life. The AMS 3D printer takes precision to the next level, making it perfect for intricate designs.

Key features include:

- First Stage Feeders: Detect and load filaments.

- Filament Hub: Combines feeding paths and provides an additional driving force.

- Buffer: Regulates filament flow to the extruder.

These components work together, providing high-quality, multicolor prints with minimal effort.

Advancements in Multicolor 3D Printing

Enhanced Creativity

Multicolor 3D printing opens a new dimension for creative expression, especially with AMS 3D printers. Combining multiple filaments, designers can bring intricate multicolor models to life. When I first saw an AMS 3D printer in action, I was blown away by its precision and color transition capabilities.

The device seamlessly switched between different hues, creating a stunning multicolor masterpiece. These printers offer features like automated color changes and integrated software for specific color gradients. This innovation pushes creative boundaries, enabling designs once deemed impossible.

Improved Efficiency

Efficiency is a game-changer with multicolor AMS 3D printers. These printers reduce manual intervention, automatically switching filaments during the print process. When using an AMS 3D printer, print times decreased significantly because of the automated material switching.

The printer’s sensors monitor filament usage, ensuring continuous operation without the need for human input. The result is maximized printing efficiency, reducing wait times, and enhancing overall productivity. Improved filament management leads to less waste and lower operational costs, benefiting both hobbyists and professionals.

Key Features of AMS

AMS 3D printers revolutionize multicolor printing by making it accessible and user-friendly. Their advanced technology simplifies the process, allowing users to create intricate, colorful designs with ease. This innovation opens new possibilities for hobbyists and professionals alike, enhancing creativity and efficiency in 3D printing projects.

Filament Management

Managing filaments gets streamlined with AMS 3D printers. They automatically switch between up to four filaments, reducing manual loading. This system includes essential components like First Stage Feeders, a Filament Hub, and a Buffer.

These elements work in sync to deliver continuous printing without interruptions. Once, I set up an AMS 3D printer for a complex project, and the smooth, uninterrupted filament transitions saved hours of manual work.

Colorizing Models

Colorizing models with AMS 3D printers has never been easier. AMS technology enables precise color changes during printing.

This capability broadens creative possibilities by allowing intricate, multicolor designs. Integrated software ensures color gradients are accurate and highly customizable. For example, Bambu Lab AMS printer can handle complex color patterns seamlessly, bringing even the most detailed designs to life.

Slicing Parameters

Optimizing slicing parameters is crucial for high-quality prints. AMS 3D printers offer advanced slicing software that tailors settings for multicolor printing. Users can adjust layer heights, speeds, and support structures to suit specific models.

The software ensures efficient material use and minimizes waste. I found the slicing software intuitive, making it simple to fine-tune parameters for different projects, enhancing both quality and efficiency.

Applications of Multicolor 3D Printing

AMS technology enables multicolor 3D printing, expanding possibilities for various applications. Its capabilities range from prototyping to educational projects, offering versatility and creativity in design. This technology enhances the functionality and appeal of 3D printed objects, making it a valuable tool for diverse fields.

Prototyping and Product Design

Multicolor 3D printing enhances prototyping by enabling detailed, vibrant prototypes. Designers can visualize products accurately, which improves decision-making processes.

When I first tried an AMS 3D printer for a prototype, seeing the multi-color layers brought my model to life in ways that traditional methods couldn’t. It cut down on the back-and-forth discussions since everyone could see the intended design clearly.

Customization and Personalization

Personalizing items like phone cases, jewelry, or accessories becomes straightforward with AMS 3D printers. Users can easily switch between colors, creating truly customized pieces that reflect individual preferences.

I printed a custom bracelet with multiple colors for a friend, and the detail made it look professionally crafted. Multicolor customization creates memorable, personalized gifts that standard 3D printers can’t match.

Educational and Artistic Projects

In classrooms and art studios, multicolor 3D printing transforms how projects are approached. Teachers can create engaging, colorful models that capture students’ attention. Artists gain the ability to bring intricate, multicolor designs to life.

I once used an AMS 3D printer to create a detailed model of a coral reef for a school project; the vibrant colors made my presentation stand out and engaged my classmates in a way that monochrome models wouldn’t have.

Challenges and Solutions

Color Transition Management

One major challenge in 3D printing with AMS is color transition management. Switching between multiple colors quickly can result in bleeding or unwanted mixing.

The Bambu Lab’s AMS 3D printer handles this with precision. It minimizes filament waste and optimizes purge sequences. I once printed a complex model with four colors and noticed smoother transitions after tweaking the filament settings and using the printer’s built-in features.

Print Quality and Speed

Balancing print quality and speed is another hurdle. High-resolution prints take time, which can be frustrating. The AMS 3D printer offers adjustable settings to tackle this.

Users can choose between different layer resolutions and balance between detail and print time. In my experience, experimenting with these settings helped me achieve detailed results without long waiting periods.

By addressing these challenges, the AMS technology paves the way for better, more colorful 3D prints.

Future Trends in Multicolor 3D Printing

Integration with AI and Machine Learning

Integrating AI and machine learning with AMS 3D printers boosts efficiency and accuracy. These technologies analyze print patterns to predict potential issues, optimizing the print process from start to finish. Once, I had a project with intricate color details that seemed impossible to manage.

The AI-driven system adjusted the slicing parameters, making the impossible, possible. This level of automation not only reduces errors but also cuts down on print time, making the process smoother and more reliable.

Expanding Material Options

New materials for AMS 3D printers are constantly emerging, enhancing the scope of multicolor 3D projects. These include flexible filaments, composite materials, and eco-friendly options. Recently, I experimented with a flexible material for a custom figurine.

The ease with which the AMS printer handled the different filaments amazed me, allowing for a colorful and flexible final product. This versatility makes AMS 3D printers adaptable for diverse applications from prototyping to artistic ventures.

Conclusion

My first encounter with an AMS 3D printer was a game-changer. It transformed my projects by enabling complex multicolor designs effortlessly. These printers not only save time and reduce filament waste but also offer a high level of detail and quality. I could switch between up to four colors smoothly, optimizing my print jobs.

Integrated AI predicted issues and adjusted settings in real-time, making the whole process more efficient. The addition of flexible filaments expanded my creative possibilities, making AMS 3D printers essential for both prototyping and artistic projects.