DIY Sound Absorbing Panels That Actually Reduce Noise

Noise from neighbors, traffic, or home activities drives people crazy. Professional soundproofing costs hundreds or thousands of dollars, making it unrealistic for most budgets.

But there’s a better way. DIY sound absorbing panels offer a practical solution that actually works. These homemade acoustic treatments can dramatically reduce unwanted noise at a fraction of the cost.

With basic materials and simple tools, anyone can build effective panels and finally enjoy some peace and quiet.

What DIY Sound Absorbing Panels Actually Do

DIY sound-absorbing panels work by trapping sound waves and stopping them from bouncing around a room. Here’s what they accomplish:

- Reduce Echo and Reverberation: They soak up sound waves that would normally bounce off hard surfaces like walls and ceilings.

- Lower Overall Noise Levels: The panels absorb sound energy, making rooms noticeably quieter.

- Improve Sound Clarity: By cutting down on echo, voices and music become clearer and easier to understand.

- Block Sound Transfer Between Rooms: When placed strategically, they help prevent noise from traveling through walls.

- Create Better Acoustics: They balance the sound in a space, making it more comfortable for listening or recording.

- Minimize Outside Noise Intrusion: While not completely soundproof, they do dampen external sounds that enter the room.

- Absorb Specific Frequency Ranges: Different materials and thicknesses target different sound frequencies, from deep bass to high-pitched sounds.

Tools and Materials Required

Building effective acoustic panels doesn’t require a fully stocked workshop. Here’s everything needed to get started, from basic tools to the right insulation materials.

| Category | Items |

|---|---|

| Tools | Hand saw or circular saw, drill, screwdriver bit, staple gun, tape measure, square, utility knife, hammer |

| Safety gear | Gloves, dust mask or respirator, safety glasses |

| Frame materials | Timber for frame, wood screws, and optional wood glue |

| Side panels | Thin plywood, particle board, or similar lightweight board |

| Backing fabric | Breathable weed membrane or similar fabric |

| Insulation | Recycled denim, hemp fiber, wood fiber, or high-density recycled foam |

| Finishing fabric | Acoustically transparent fabric of choice |

| Mounting hardware | Picture hooks, picture wire, and wall hooks rated for weight |

| Optional extras | Decorative outer frame timber, nails or brads, and corner spacers for a larger air gap |

Step-by-Step Instructions to Build High-Performance Acoustic Panels

Creating professional-quality panels at home is straightforward when following the right process. These six steps break down the entire build from start to finish.

Step 1: Plan Your Panel Size and Prepare the Frame Pieces

Start by deciding the final size and thickness of your acoustic panel based on your room and the insulation available in your area. A common size is 120 × 60 cm or 4 × 2 ft, but you can adjust this easily.

Cut your wooden frame pieces so that the long vertical pieces carry the weight of the panel, with the shorter horizontal piece sitting on top.

This layout creates a much stronger frame while keeping the panel lightweight and easy to hang.

Step 2: Assemble a Strong Wooden Frame

Pre-drill all screw holes to prevent splitting and ensure clean joints. Assemble the frame using simple 90-degree joints, checking that everything sits square before tightening the screws.

One good quality screw per corner is usually enough if the wood is sound. Once assembled, attach your hanging hooks about 30 cm or 1 ft down from the top on both sides, keeping them perfectly level.

This is much easier to do now than later.

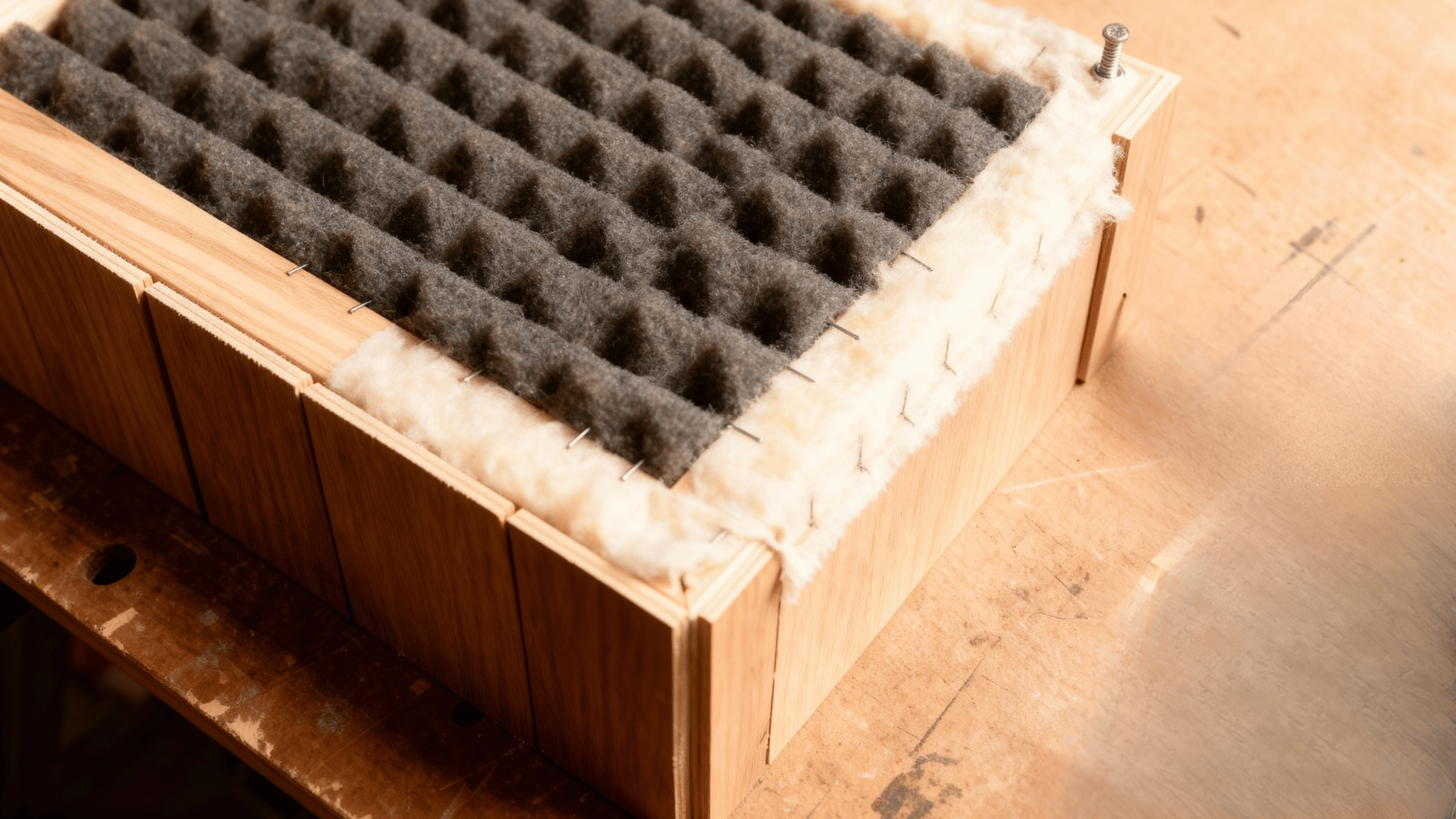

Step 3: Attach the Side Panels and Protect the Edges

Fix thin side boards around the perimeter of the frame to create the depth needed for your insulation.

These side panels are not structural, so lightweight materials like thin plywood or particle board work well. Staples, nails, or glue can all be used. Test the strength as you go and choose what holds best.

Finish the corners with fabric or clear tape to prevent sharp edges from damaging the fabric later.

Step 4: Seal the Back of The Panel with Breathable Fabric

Lay the panel face down and staple a strong, breathable fabric to the inside of the rear frame.

Gardening weed membrane works very well here as it is durable, affordable, and prevents insulation fibers from escaping.

Stapling from the inside creates a small air gap behind the insulation, which improves acoustic performance once the panel is mounted on the wall.

Step 5: Install the Acoustic Insulation Safely

Insert your chosen insulation from the front of the panel, making sure it fits snugly without being compressed. Compression reduces acoustic effectiveness.

Safe alternatives such as recycled denim, hemp fiber, wood fiber, or high-density recycled foam are recommended. Aim for insulation with a density between 20 and 30 kg per cubic meter for best results.

If trimming is needed, cut carefully and keep edges neat.

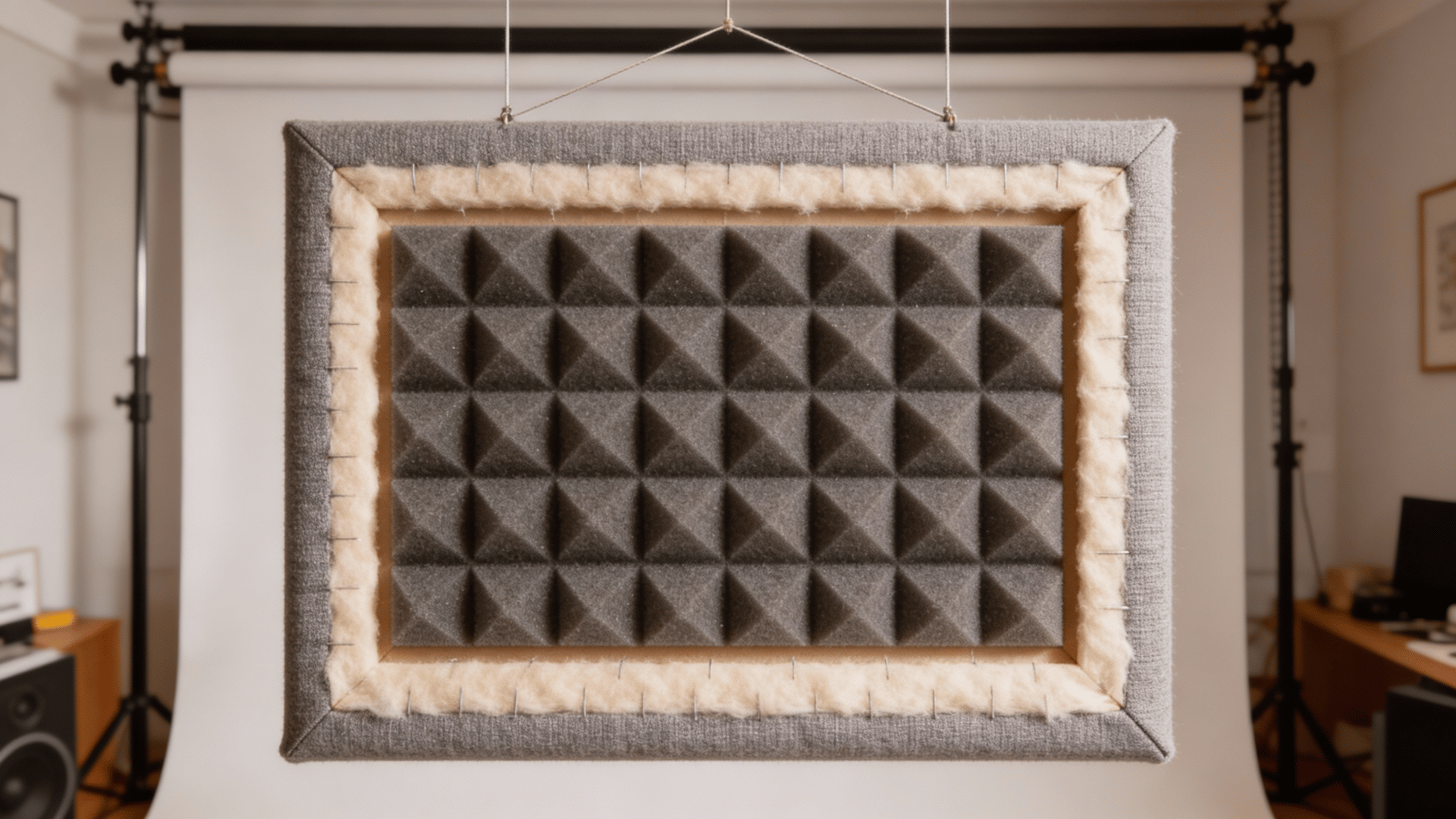

Step 6: Wrap the Panel and Mount It on The Wall

Place the panel face down on your finishing fabric, leaving enough excess on all sides. Staple one side first, apply gentle tension, then staple the opposite side.

Work slowly around the corners, folding and tucking the fabric neatly for a clean finish. Attach the picture wire between the hooks, hang the panel on a wall hook rated for the weight, and enjoy the improved sound.

If desired, you can add an external wooden trim for aesthetics, keeping in mind the added cost and weight.

Best Placement for DIY Sound Absorbing Panels

The best placement for DIY sound-absorbing panels is at the first reflection points, where sound from speakers or your voice bounces directly off nearby surfaces before reaching your ears.

These spots are typically on the side walls, ceiling, and sometimes the desk area. Treating them first delivers the biggest improvement in clarity and reduces echo quickly.

Panels placed behind speakers help control early reflections, while panels behind the listening or recording position reduce rear wall bounce and flutter echo.

In small rooms, adding panels to bare walls is often more effective than spreading them evenly. Corners can also benefit, but thin panels work best on flat surfaces rather than as bass traps.

Always start with a few well-placed panels and add more only if needed.

Upgrades to Improve DIY Sound Absorbing Panels

Here are simple upgrades that can noticeably improve the performance of DIY sound-absorbing panels without rebuilding them:

- Increase panel thickness to improve absorption of lower frequencies

- Add a small air gap between the panel and the wall to boost efficiency

- Use higher-density insulation for better mid and low-frequency control

- Replace decorative fabric with fully breathable acoustic fabric if needed

- Double-layer the insulation without compressing it

- Mount panels at first reflection points instead of random placement

- Use thicker panels or stacked panels for corner problem areas

- Seal all edges properly to prevent fiber leakage and fabric sagging

Common Mistakes with DIY Sound Absorbing Panels

Below is a quick table highlighting the most common mistakes people make with DIY sound absorbing panels and how to avoid them for better results:

| Common Mistake | Why It Reduces Performance | What to Do Instead |

|---|---|---|

| Expecting soundproofing | Panels absorb echo, not block sound from leaving a room | Use panels for reflections, not noise isolation |

| Using thin foam panels | Thin foam absorbs very limited frequencies | Use thicker insulation-based panels |

| Placing panels randomly | Random placement wastes material and effort | Treat the first reflection points first |

| Compressing insulation | Compression reduces sound absorption | Fit insulation snugly without pressure |

| Using non-breathable fabric | Sound cannot reach the insulation | Test fabric for airflow before use |

| Ignoring safety measures | Fibers can escape and cause irritation | Seal edges and use safe insulation |

| Weak wall mounting | Panels may fall or damage walls | Use hardware rated for the panel weight |

| Treating corners with thin panels | Thin panels do little for low frequencies | Use thicker panels or bass traps for corners |

The Bottom Line

Building DIY sound absorbing panels turns out to be simpler than most people expect. With basic tools, affordable materials, and a few hours of work, anyone can create acoustic treatments that genuinely reduce noise.

The panels absorb unwanted sound, cut down echo, and make any room more comfortable. Start with just two or three panels at key reflection points and see the difference for yourself.

There’s no need to spend thousands on professional solutions when homemade versions deliver real results.

Grab your materials, follow the steps, and take control of your space’s acoustics. Your ears will thank you, and so will your wallet.