DIY Kitchen Table Made Simple and Budget Friendly

Kitchen tables can cost a fortune, and finding one that fits your space and budget isn’t always easy. But what if you could build your own DIY kitchen table without breaking your budget or needing advanced skills?

This guide will show you how to create a simple, affordable kitchen table using basic tools and materials.

You’ll learn step-by-step instructions, budget-friendly material choices, and practical tips that make the process straightforward, even for beginners.

Why Build a DIY Kitchen Table Instead of Buying?

Building a DIY kitchen table offers several advantages over buying one from a store. First, it saves money.

A decent table can easily cost $500 or more, but making one yourself often costs half that amount. Second, customization becomes possible.

Anyone can adjust the size, height, and finish to match their exact needs and style preferences. Third, the quality is often better.

Store-bought tables frequently use particleboard or cheap materials, while a homemade table can feature solid wood that lasts for years.

Also, there’s genuine satisfaction in creating something functional with your own hands. Friends and family will admire the craftsmanship, and people will gain a unique piece that tells a story.

The process isn’t complicated either; basic woodworking skills are enough to complete most designs successfully.

How to Measure Your Space and Choose Table Dimensions?

Getting the correct table size prevents cramped spaces and ensures comfortable seating. Here’s how to measure correctly:

- Measure the Room Dimensions: Use a tape measure to record the length and width of the dining area

- Allow 3 Feet of Clearance: Leave space around the table for chairs to pull out and people to walk

- Calculate Seating Needs: Plan for 24 inches of table width per person for comfortable elbow room

- Consider Table Height: Standard dining tables are 28-30 inches tall; adjust based on chair height

- Account for Table Shape: Rectangular tables fit narrow spaces; round tables work better in square rooms

- Mark the Floor: Use painter’s tape to outline the planned table size and walk around it

- Check Door Clearances: Ensure the finished table can fit through doorways if needed later

- Think About Daily Use: Consider how many people typically eat versus the maximum capacity needed

Tools and Materials for a Simple DIY Dining Table

Having the right supplies ready before starting saves time and frustration. Here’s everything needed to build a sturdy, attractive table without making extra trips to the hardware store.

| Tools | Materials |

|---|---|

| Circular saw | Hardwood boards (for example, white oak) |

| Straight edge guide | Wood glue |

| Drill with depth stop | Dowels |

| Doweling jig | Sawdust for filler |

| Belt sander (80 and 120 grit belts) | Packing tape for cauls |

| Bar clamps and F-style clamps | Metal table legs or custom base |

| Wire brush or grinder attachment | Acetone for cleaning metal |

| Safety gear (dust mask, glasses, gloves) | Paste wax for metal protection |

Building Your DIY Kitchen Table: Simple Steps Guide

Creating a DIY kitchen table becomes manageable when broken down into clear steps. This section shows, through each phase of construction, from cutting the first board to applying the final finish.

Step 1: Select and Prepare Your Lumber

Choose high-quality boards for your tabletop, ideally thick hardwood such as white oak.

If your lumber supplier offers surfacing services, have them plane and straight-line rip the boards so they arrive flat and with one perfectly straight edge.

If not, you can achieve this at home using a planer and a straight-edge guide. Once your boards are home, cut them into rough lengths, leaving extra room for trimming later.

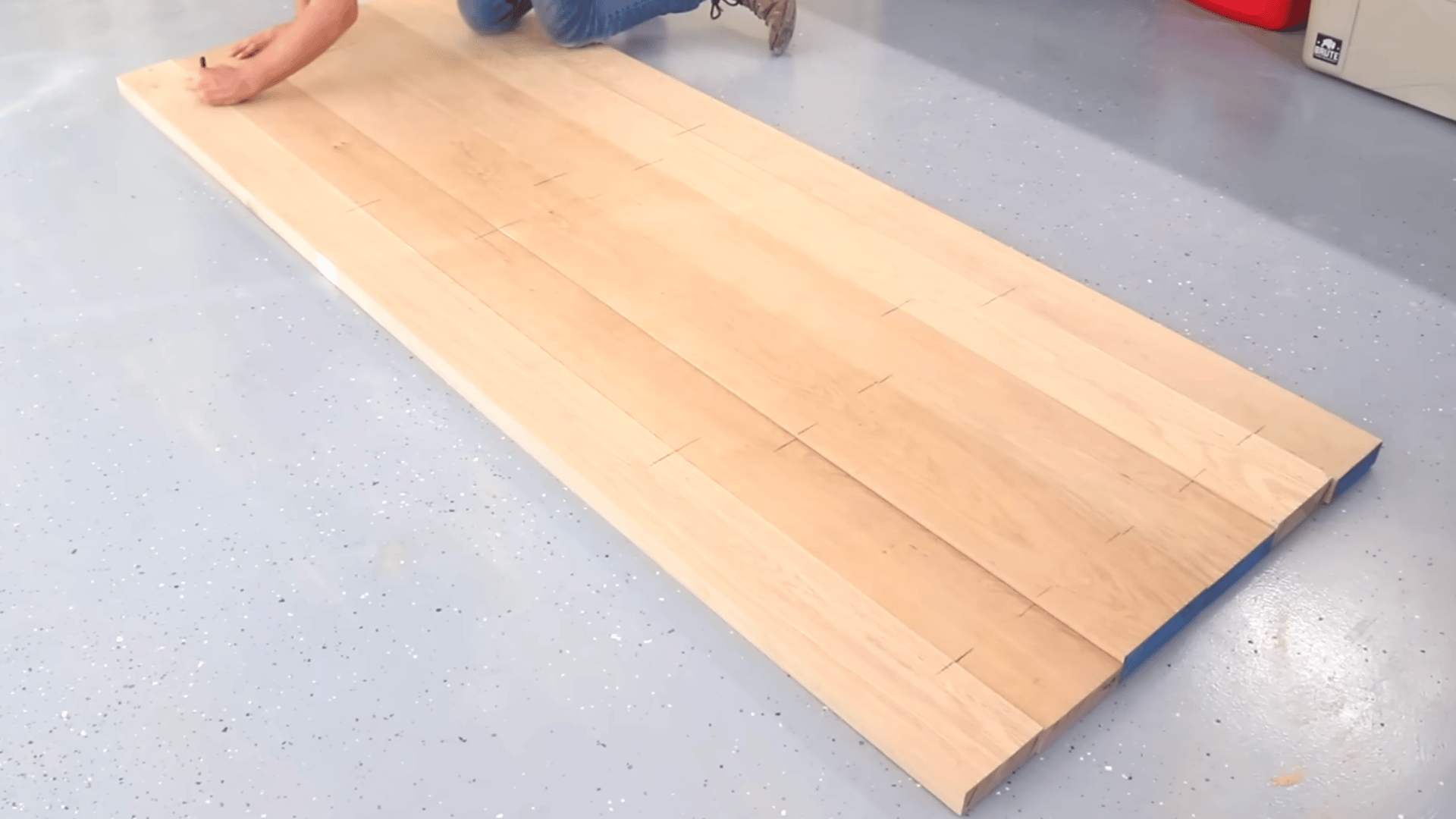

Then cut each board to its final width, pairing them so the tabletop layout feels balanced and symmetrical.

Step 2: Mark and Drill for Dowels

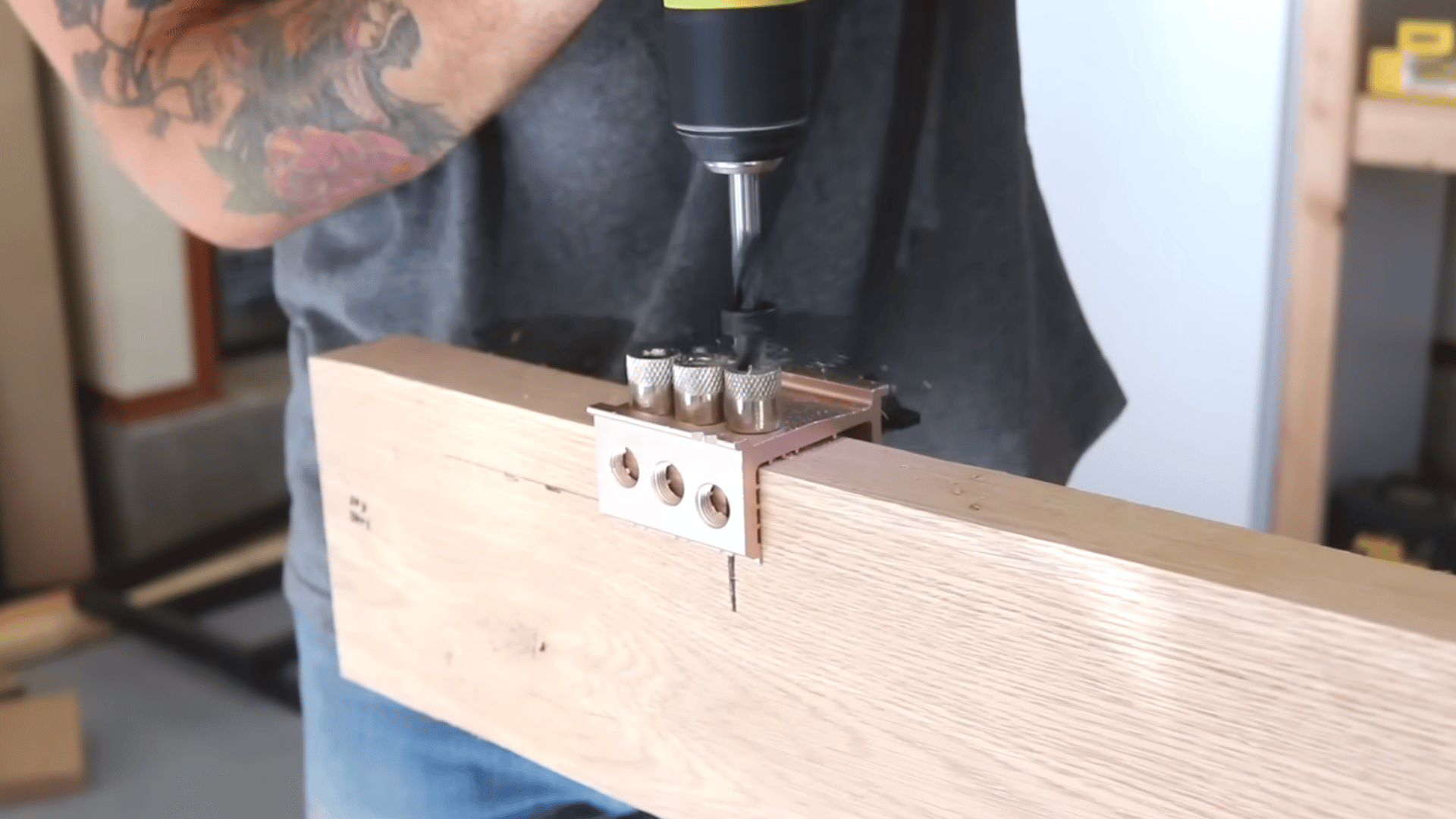

Lay the boards in their final order and mark where each joint will be reinforced with dowels. A simple doweling jig makes this step easy and beginner-friendly.

Align the jig with each mark, then drill holes using a drill equipped with a depth stop. Before moving on, test the fit to ensure all dowels align perfectly.

Glue dowels into one board at each joint, so they stay in place during assembly, making the glue-up smoother and less stressful.

Step 3: Set Up for Glue-Up Using Cauls

Create two or more cauls using straight 2x4s with packing tape on one face so the glue won’t stick. These cauls will help keep the tabletop flat during clamping.

Apply a generous coat of wood glue along each joint, spreading it evenly with a gloved hand. Assemble the boards, attach your clamps, and place the cauls across the width of the tabletop.

Gently tighten everything until the boards pull together and sit flat. Let the glue dry overnight so the panel becomes strong and stable.

Step 4: Fill Imperfections and Flatten the Surface

Once the glue has cured, mix a little sawdust with wood glue to make a custom filler that matches your tabletop perfectly.

Use this mixture to fill any small gaps, knots, or cracks. After it dries, begin flattening the tabletop with a belt sander, starting at 80-grit to remove uneven spots.

Move to 120-grit for smoothing. Wear your preferred dust mask so sanding stays comfortable and safe.

Step 5: Trim the Tabletop and Prepare the Base

Use a circular saw paired with a straight-edge guide to trim the tabletop to its final clean dimensions. Switch to a fresh blade to get crisp cuts with minimal tear-out.

For the base, you can use prefabricated steel legs or build your own wood or metal version.

If the steel legs come unfinished, clean them with a wire brush to remove rust or scale, wipe with acetone, and finish them with a protective paste wax for a smooth, polished look.

Step 6: Apply the Final Finish and Assemble

Choose a wood finish that brings out the natural richness of your hardwood; an oil-and-wax blend works beautifully for warmth and depth.

Apply multiple coats, allowing proper drying time between each one. Once the finish has cured, attach the metal legs securely to the underside of the tabletop.

Give everything a final wipe down and enjoy the beautiful modern dining table you created with just a few tools and a hefty dose of craftsmanship.

Estimated Total Budget:

Low End: About 360 USD

High-End: About 700 USD

Want to see the process in action? Check out the YouTube video below.

Make It Truly Yours: Customization Ideas

A DIY kitchen table doesn’t have to look plain or basic. Adding personal touches modifies it from a simple project into a statement piece that reflects individual style and needs.

1. Choosing the Right Wood Finish

The finish dramatically changes how the table looks and feels. Light stains like natural oak or whitewash create a bright, modern appearance that opens up smaller kitchens.

Darker finishes, such as walnut or espresso, bring warmth and traditional charm. Clear polyurethane protects the wood while showing off natural grain patterns.

2. Adding Storage Features

Built-in storage makes the table more functional for everyday life. Drawers underneath can hold napkins, placemats, or utensils within easy reach.

Open shelves on the sides provide spots for cookbooks or decorative baskets. Some builders even add hidden compartments for valuable items.

3. Selecting Leg Styles

Table legs define the overall character and stability. Straight, tapered legs suit modern or farmhouse designs and are easier to build for beginners.

Turned legs with decorative details add Victorian or traditional flair but require a lathe or pre-made options from hardware stores.

Hairpin legs create an industrial look and bolt onto the tabletop. Trestle bases offer maximum legroom and work well for longer tables.

4. Mixing Materials

Combining different materials adds visual interest. A wooden top paired with metal legs creates an industrial-chic vibe that’s popular right now.

Concrete overlays on plywood bases deliver a contemporary edge with surprising durability.

Some people use reclaimed barn wood for the top and new lumber for the frame, blending rustic and modern elements beautifully.

Care and Maintenance so Your DIY Table Lasts

Proper care keeps a DIY kitchen table looking great and functioning well for decades. Follow these simple maintenance tips:

- Wipe Spills Immediately: Liquids can stain or warp wood if left sitting for too long

- Use Coasters and Placemats: Protect the surface from heat marks, water rings, and scratches

- Clean with Mild Soap: Mix dish soap with warm water; avoid harsh chemicals that damage finishes

- Reapply Finish Yearly: Add a fresh coat of polyurethane or oil to maintain protection and shine

- Tighten Loose Screws: Check joints and hardware every few months and tighten as needed

- Avoid Direct Sunlight: Prolonged exposure fades wood color and weakens the finish over time

- Use Furniture Pads: Place felt pads under objects to prevent scratches when sliding items across

- Sand and Refinish when Needed: Light sanding removes surface damage; refinishing restores original beauty

- Keep Humidity Stable: Extreme dryness or moisture causes wood to crack or swell

Conclusion

Building a DIY kitchen table isn’t just about saving money; it’s about creating something that truly fits your home and lifestyle.

From measuring the space correctly to adding custom finishes and storage features, every decision makes the table uniquely yours.

With basic tools, affordable materials, and proper maintenance, this table will serve meals and memories for years to come. So grab those supplies and start building.

The satisfaction of sitting around a table made with your own hands beats any store-bought option. Your kitchen deserves furniture that reflects your effort and personality.