The Truth About Living with Knob-and-Tube or Aluminum Systems

Knob and tube lacks grounding and struggles with contemporary loads, while aluminum connections can overheat from oxidation. These systems often complicate knob and tube insurance coverage, leading to higher premiums or requirements for upgrades.

Electrical rewiring cost typically ranges from $8000 to $25000 or more, depending on home size and complexity, but a professional assessment determines the best path forward for safety and compliance.

Introduction

The absence of grounding in knob and tube increases shock hazards, and brittle insulation over decades heightens fire potential under overload. Aluminum wiring, though conductive, experiences expansion and contraction that loosen connections, promoting oxidation and arcing at terminations.

Consulting licensed electricians provides clarity on conditions and viable solutions, from targeted repairs to full replacement, aligning the system with current Canadian Electrical Code requirements and regional standards. Addressing these concerns proactively supports long-term home safety and property value stability.

What Makes Knob and Tube Wiring and Aluminum Wiring Outdated

These systems served their purpose during installation periods, yet modern electrical demands have rendered them obsolete. Contemporary households rely on higher amperage loads from appliances, HVAC equipment, and electronic devices, which exceed the capacity originally designed for these older configurations.

Key Characteristics of Knob and Tube

This early system used separate hot and neutral conductors supported by porcelain knobs and tubes through framing members. It lacks a dedicated grounding conductor, a standard safety feature in current installations.

The cloth-covered rubber insulation deteriorates over time, becoming brittle and prone to cracking, especially when exposed to heat or physical disturbance. Overloading becomes a concern because circuits typically support only 15-amp service, insufficient for today’s usage patterns.

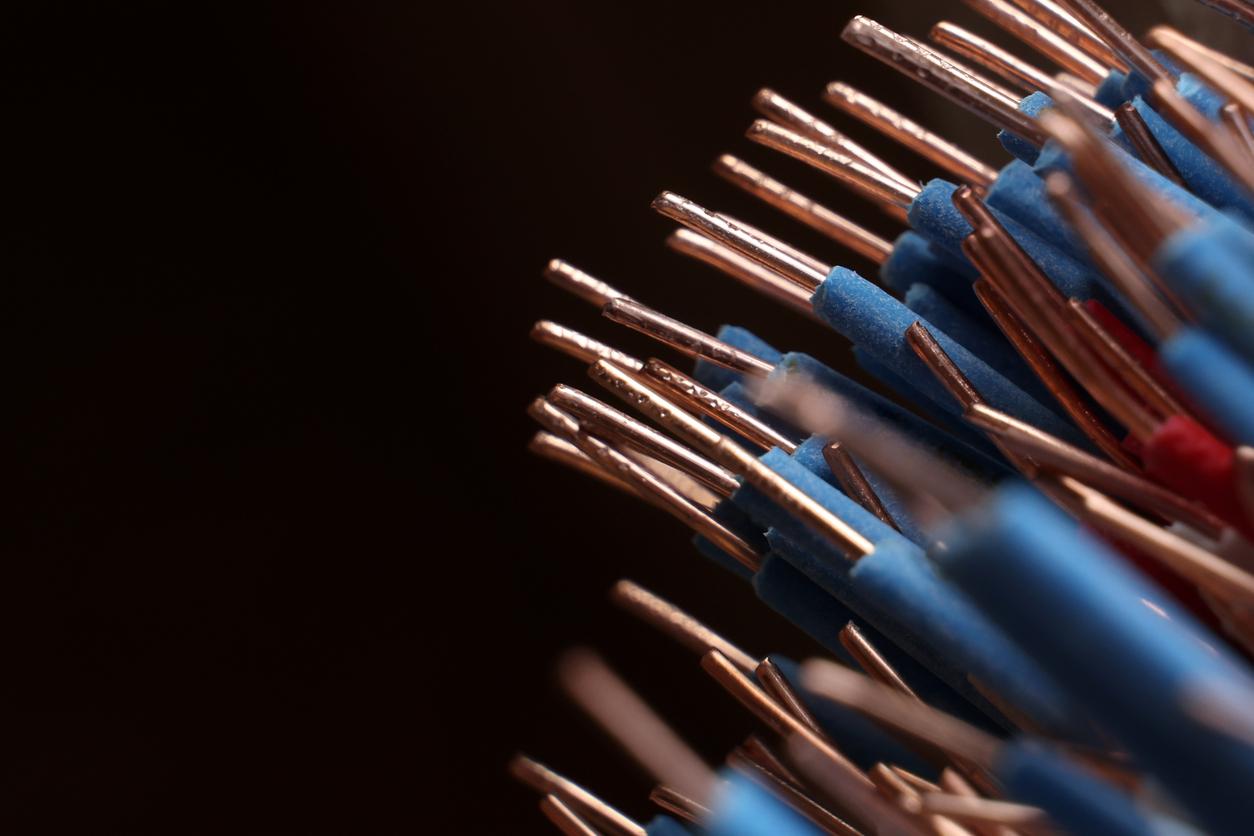

Distinguishing Features of Aluminum

Aluminum branch wiring appeared as a cost-effective alternative to copper during a material shortage era. The metal offers good conductivity, but its thermal expansion rate differs significantly from copper. Repeated heating and cooling cycles cause connections to loosen, allowing oxidation to form at terminations. This oxide layer increases resistance, generating heat that can lead to arcing or melting under sustained load.

Comparison of Outdated Systems

|

Aspect |

Knob and Tube |

Aluminum |

|---|---|---|

|

Installation Period |

Late 1800s to 1930s |

1960s to mid-1970s |

|

Grounding |

Absent |

Present (but connections problematic) |

|

Primary Material |

Copper conductors |

Aluminum conductors |

|

Main Failure Mode |

Insulation degradation, no ground |

Loose connections, oxidation at terminations |

|

Load Capacity |

Limited to lower amperage |

Adequate conductivity, but connection issues |

|

Fire Risk Factor |

Overload and exposed wires |

Overheating of devices and splices |

Schedule a professional inspection whenever purchasing or insuring an older property. Licensed electricians can assess wire condition through visual examination and thermal imaging to identify hidden deterioration before issues escalate.

Such systems function adequately if loads remain light and modifications stay minimal. The reality is that evolving building codes and increased power consumption highlight their limitations, prompting many homeowners to consider upgrades for reliability and compliance.

Understanding the Safety Risks and Insurance Challenges

Knob & tube and aluminum wiring carry distinct safety concerns that stem from their design and age-related degradation. These risks become more pronounced as electrical loads increase and materials naturally deteriorate over decades.

Primary Safety Concerns with Knob and Tube

The absence of a grounding conductor represents the most significant hazard. Without grounding, faults can energize metal fixtures, appliances, or junction boxes, creating shock risks for occupants.

The rubber insulation, often wrapped in cloth, hardens and cracks with age, exposing live conductors to framing members or insulation materials. Overloading circuits designed for lower amperage frequently causes excessive heat buildup, raising the potential for electrical fires.

Key Safety Issues with Aluminum

Aluminum conductors expand and contract more than copper during normal heating cycles from current flow. This movement loosens connections at outlets, switches, and splices. The resulting loose connections allow oxidation to form, which increases electrical resistance and generates localized heat. Over time, this process can lead to arcing, melting of plastic devices, or ignition of nearby combustible materials.

Insurance Implications for Outdated Electrical Systems

Home insurers classify knob and tube wiring and aluminum wiring replacement as higher-risk features because of documented fire statistics associated with these systems. Many providers limit coverage, exclude certain perils, or require upgrades before issuing a policy. Homeowners often face higher premiums, sometimes 20 to 50 percent above standard rates, or face outright denials in competitive markets.

Common Insurance Responses

Contact your insurer early when purchasing or refinancing a home with these systems. A detailed electrical inspection report from qualified professionals can sometimes mitigate premium increases or coverage restrictions.

- Require full or partial rewiring before binding coverage

- Apply surcharges until remediation completes

- Limit liability coverage for fire claims related to the electrical system

- Demand a professional inspection report confirming safe condition

The result is that these older installations create ongoing uncertainty for homeowners. Many insurers now mandate upgrades to modern copper wiring with proper grounding and GFCI protection to align with current safety standards and reduce overall risk exposure.

Replacement Options and Electrical Rewiring Cost Considerations

Homeowners facing outdated electrical wiring must weigh several practical paths forward. The decision typically balances immediate safety needs, long-term reliability, budget constraints, and property value impacts. Full replacement remains the gold standard for eliminating risks, though targeted approaches sometimes suffice depending on system condition and usage patterns.

Evaluating Full Electrical Rewiring

Complete rewiring replaces every branch circuit with modern copper conductors, proper grounding, and updated panel capacity. This approach brings the entire system into compliance with the latest Canadian Electrical Code requirements. It eliminates hazards from degraded insulation, loose connections, and inadequate amperage while supporting contemporary loads without modification concerns.

Partial Remediation Strategies

In select cases, professionals address specific problem areas rather than replacing everything. For aluminum wiring, pigtailing with approved copper-to-aluminum connectors or COPALUM crimps at every termination point reduces overheating risks. Knob and tube insurance sometimes benefits from dedicated grounding additions or circuit splitting to prevent overloads on original conductors.

Factors Influencing Cost

Several variables determine the final investment required for upgrades.

- Home size and layout: Larger floor areas or multi-storey designs increase labour and material needs.

- Accessibility: Finished basements, plaster walls, or complex framing raise difficulty and expense.

- Panel upgrade requirements: Many older homes need a new 200-amp service entrance to handle modern demands.

- Permits and inspections: Municipal requirements add administrative costs and time.

- Scope of work: Full replacement versus targeted fixes produces significantly different price ranges.

Typical electrical rewiring cost in Canadian markets falls between $8000 and $25000 for an average single-family home, though complex projects can exceed this range. Quotes vary widely based on local labour rates and material specifications.

On the other hand, delaying action often proves more expensive through higher insurance premiums, restricted resale options, or emergency repairs after a failure. Investing in modern wiring protects occupants, supports energy-efficient upgrades, and positions the property favourably for future buyers.

Safeguarding Your Home with Modern Electrical Standards

The presence of knob and tube wiring or aluminum wiring in an older home demands careful attention rather than immediate alarm. These systems once met the needs of their era, yet evolving electrical demands, material aging, and stricter safety codes have exposed their limitations. Professional inspections reveal whether the installation remains viable under controlled conditions or requires intervention to prevent hazards.

Prioritizing safety through accurate assessment protects occupants, supports reliable performance, and maintains property insurability. Many homeowners find that strategic upgrades deliver measurable benefits in peace of mind, energy efficiency, and long-term value. When addressing outdated electrical wiring, the focus stays on compliance, durability, and future readiness.