3 Essential Investments for Safe, Efficient Job Sites

Safe and efficient job sites rely on more than just skilled labor; they require strategic equipment choices. High-quality aftermarket parts, certified garage lifts, and organized tool systems collectively reduce downtime and prevent injuries. These upgrades directly address the root causes of delays, such as mechanical failure and disorganized workspaces.

Missed deadlines and profit loss often trace back to equipment failures or risky maintenance practices. Labor productivity in U.S. construction in 2023 was essentially the same as it was in 1948, highlighting a critical need for modernization. A few targeted purchases can slash risks while speeding up daily operations.

1) Upgrade to Quality Excavator Parts Before Failure Strikes

The Problem

An excavator cylinder seizing during a trenching job can leave an entire crew idle. Unplanned downtime costs contractors significantly in labor and rental penalties. Mechanical failure is also linked to a high percentage of heavy-equipment injuries on-site.

The Solution

Proactive replacement with premium components reduces surprise breakdowns and keeps critical assets in rotation. Sourcing HW Part Store’s heavy-duty aftermarket excavator parts allows fleet managers to access a vetted inventory of seal kits and components. This minimizes the gap between a diagnosis and the final repair.

Why It Pays Off

- Reduced Failure Rates: Preventive swapping of parts cuts failure rates significantly.

- Predictable Schedules: Maintenance windows become predictable rather than reactive.

- Lower TCO: Avoiding run-to-failure tactics lowers the total cost of ownership.

|

Warning/Important: Relying on run-to-failure tactics creates a liability, not savings. With unplanned downtime costing up to $260 per hour, a single seized cylinder can quickly erase a week’s worth of project profit margins. |

|---|

2) Install Garage Lifts to Service Heavy Equipment Safely

The Problem

Improvising with jack stands creates severe safety hazards in maintenance bays. Falls, slips, and trips accounted for 35.3 percent of the workplace deaths within construction and extraction occupations in 2020. Makeshift supports often lack the stability required for heavy machinery service.

The Solution

Investing in lifts rated for loaders and service trucks is essential for modern workshops. Shops equipped with HeavyLift Direct’s sturdy garage lift systems gain access to ALI-certified equipment designed for substantial weights. Mechanical safety locks and proper weight margins ensure a secure working environment.

Benefits

360-degree access shortens preventive maintenance cycles by roughly 30%. Ergonomic working heights reduce musculoskeletal strains, preventing costly medical claims. Integrated safety features also help create audit-ready maintenance records.

|

Pro Tip: Always maintain a 25% safety margin between a machine’s curb weight and the lift’s capacity. This buffer accounts for accumulated mud, fuel, and heavy aftermarket attachments that increase total vehicle weight. |

|---|

Mini-Sidebar: 60-Second Inspection Checklist

- Verify the capacity plate matches the vehicle’s weight.

- Check safety-lock engagement.

- Inspect hydraulic hoses for leaks.

- Ensure swing arms contact OEM lift points.

- Confirm work-area barricades are in place.

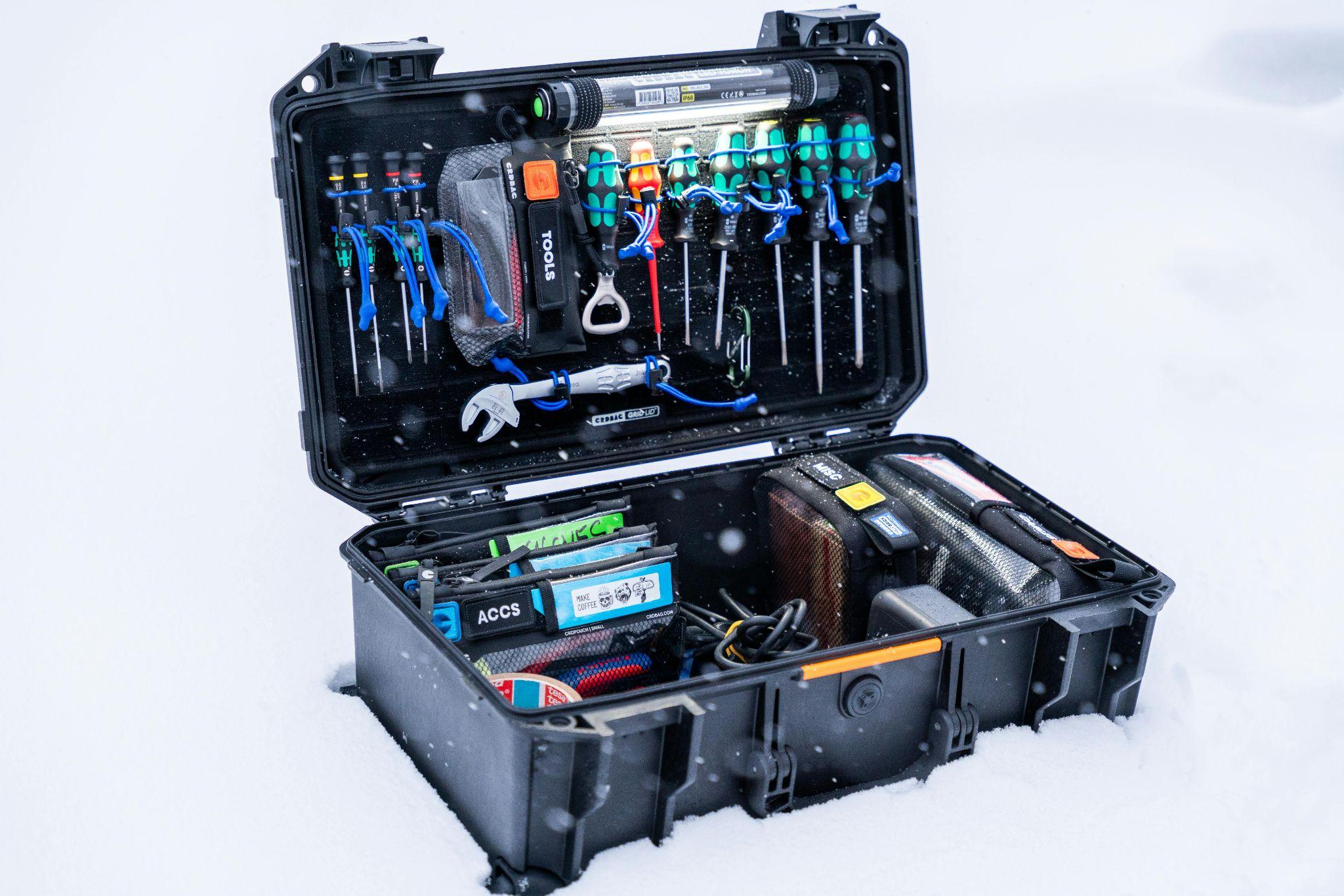

3) Adopt Organized Storage Solutions for Tools & Consumables

Image by Andreas Näslund from Pexels

Alt text: Professional tool case open in a snowy environment.

The Problem

Inefficiency drains budgets rapidly when tools are hard to find. FMI research suggests contractors lost approximately $30 billion to $40 billion to labor inefficiencies recently. Disorganized tool areas also increase trip hazards and damage expensive gear.

Solution Options

Modular cabinets with RFID tracking can alert managers when items leave the site. Shadow boards place every tool in plain view to accelerate retrieval times. Weather-sealed bins protect consumables like PPE from moisture damage.

Benefits

- Faster Retrieval: Shadow boards improve tool retrieval speed by over 10%.

- Safety: Removing clutter reduces slip and trip incidents.

- Quality Control: Proper storage keeps professional tools within calibration specs.

|

Key Insight: Disorganization is a silent budget killer. When skilled crews spend 38% of their day searching for tools, you are paying premium labor rates for an expensive game of hide-and-seek. |

|---|

Future-Ready Safety Mindset

Current investments lay the groundwork for next-generation technology. AI cameras and telematics can predict issues days before they cause failures. A clean and maintained fleet is the baseline that allows these advanced technologies to function effectively.

Time to Act

Balancing safety and productivity is the fastest route to successful project delivery. Consider immediate steps to secure your operations and budget. Start by auditing your current equipment and storage protocols.

- Swap critical wear parts before failure strikes.

- Service equipment using certified garage lifts.

- Deploy smart storage to eliminate wasted time.

Review your fleet and maintenance bays this week to identify efficiency leaks. Small changes in equipment and organization yield significant long-term returns.